- 28 Oct 2023

- 1676

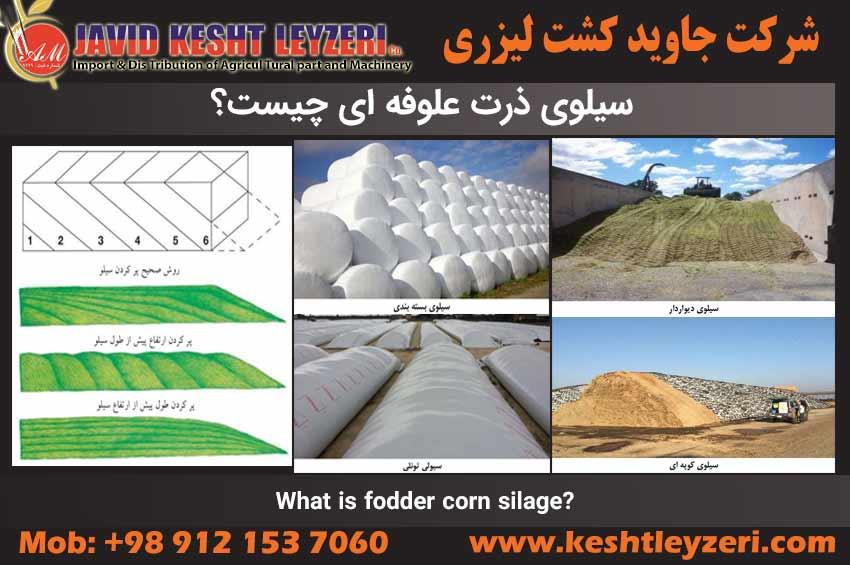

What is fodder corn silage?

Corn silage is used as a high quality fodder in many dairy farms and in some fattening farms. This product is very popular due to its high performance, good digestibility, high energy and ease of adaptation to mechanized harvesting and feeding. Fodder corn can be cultivated ideally in many regions of the country as a second crop after the fall crop. Ensiling is necessary to preserve harvested forage corn. The purpose of making silos is to preserve the harvested product by anaerobic (oxygen-free) fermentation. This process uses bacteria to convert soluble carbohydrates into acetic acid and lactic acid, or "souring" the product. In a completely sealed silo, the product can be preserved for a long time without losing quality. To produce a high quality silage, it is necessary to carefully plant, store and harvest silage corn.

- 05 Jul 2023

- 2115

What is forage silage fermentation?

For ensiling, it stores fresh or withered fodder for fermentation and souring in a place called silo. This place should be protected as much as possible against the entry of air and the exit of gases. The act of fermentation or souring makes fodder stable and prevents fodder spoilage.

- 04 Jul 2023

- 2254

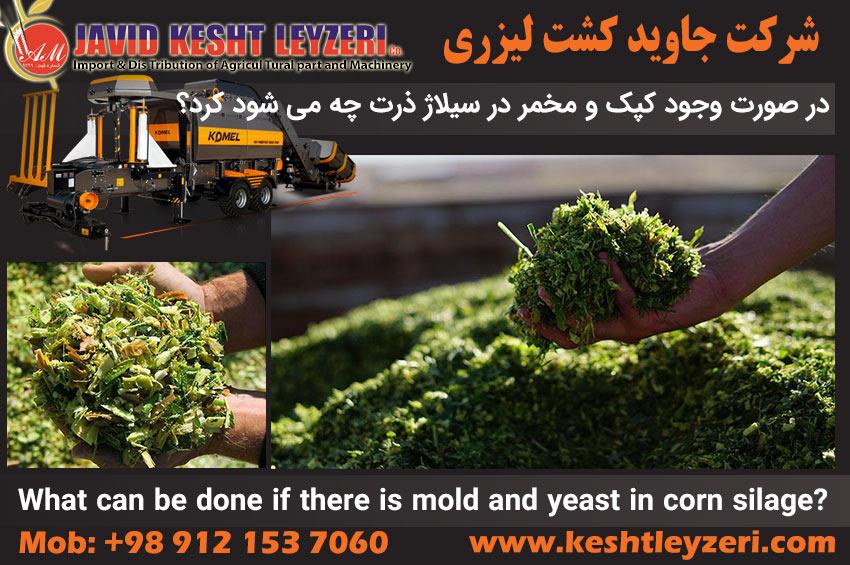

What can be done if there is mold and yeast in corn silage?

The presence of silages that are not aerobically stable is one of the most common problems on dairy farms, even in the United States. Maize silage that has not yet reached aerobic stability has characteristics such as high temperature, mold growth and unpleasant smell and mustiness that can be seen in the front parts and upper surfaces of the silage that are used on a daily basis.

- 26 Jun 2023

- 1460

Increasing the quality of produced corn silage

Fodder corn is one of the strategic inputs in the livestock industry. Several factors, including controllable managerial factors and uncontrollable environmental factors, affect the quality of fodder. Harvesting time has an effect on the quantitative and qualitative yield of corn silage.

- 06 Dec 2022

- 4448

Fodder packing machine - 1200 kg MOBILE komel - corn silage

Combine silage roll baler whose production is carried out by our firm is a machine that starts with the electric motor and that disconnect ready silage, beep pulp, fruit pulp and various green coarse fodder crops filled with tilter to the feeding tank the relation with the external environment getting into roll by pressing as stemmed, covering with the stretch and that provides a longer conservation of the products.

- 06 Dec 2022

- 5476

Fodder packing machine - 100, 200, 500, 700, 1200-1500 kg and the new mobile series of 1200 kg KOMEL

Specialized import of corn fodder packaging machine, with modern European technology

- 05 Dec 2022

- 2780

Fodder packing machine - 1200 kg komel - corn silage

The power consumption of the Komel 1200 kilo corn fodder packaging machine (RK MASTER 1200 PRO) is 60 kilowatts. It works with a 140 hp tractor (PTO) system where there is no electricity. Due to having special software, it works completely electronically and automatically.

- 03 Dec 2022

- 2432

Corn fodder packing machine - 500 kg Komel Turkey (corn fodder silage)

The power consumption of the Komel 500 kg corn fodder packaging machine (RK MASTER 500 PRO) is 40 kW.

- 03 Dec 2022

- 3090

Fodder packing machine - 700 kg, Komel Turkey company (corn fodder silage)

Hourly capacity of RK MASTER 700 PRO is, 55 to 60 bales.

- 01 Dec 2022

- 2039

Maize fodder packaging machine - 200 kg, Komel Turkey company (maize silage packaging)

It is a machine which rolls ready silage, beet pulp, fruit pulp and various green forage plants which are filled in feeding bunker with dumper truck by pressing them in bales.