What is fodder corn silage?

javid keshtleyzeri Co.ltd

In this section, the following topics are mentioned under the title of fodder corn silage:

What is corn silage?

What is the production of silage corn?

What are the effects of living and non-living stresses on fodder corn?

What is the fermentation process of corn silage?

What are the types of corn silage?

How to preserve the quality of corn silage?

What are the dimensions of the fodder silo?

What are additives to silage?

In the following, the above contents will be reviewed.

What is corn silage?

Corn silage is used as a high quality fodder in many dairy farms and in some fattening farms. This product is very popular due to its high performance, good digestibility, high energy and ease of adaptation to mechanized harvesting and feeding. Fodder corn can be cultivated ideally in many regions of the country as a second crop after the fall crop. Ensiling is necessary to preserve harvested forage corn. The purpose of making silos is to preserve the harvested product by anaerobic (oxygen-free) fermentation. This process uses bacteria to convert soluble carbohydrates into acetic acid and lactic acid, or "souring" the product. In a completely sealed silo, the product can be preserved for a long time without losing quality. To produce a high quality silage, it is necessary to carefully plant, store and harvest silage corn.

What is the production of silage corn?

It is better to comply with the soil test and use organic fertilizers instead of adding chemical fertilizers. A good field of silage corn can produce between 60 and 100 tons of forage per hectare. This amount of forage removes approximately 170 kg of nitrogen (N), 70 kg of phosphate (P2O5) and 180 kg of potash (K2O) from each hectare of soil. In contrast, a 6-ton crop of grain corn harvests only 100 kg (N), 40 kg of phosphate, and 40 kg of potash from the soil. Therefore, ensure that the soil is sufficiently fertilized and has the right acidity (PH) level and nutrients for the silage corn crop to grow well.

It is very important to choose fodder corn hybrid seeds with high yield, appropriate growth period and resistance to pests and diseases. It should be ensured that the right seed is selected for the desired field and climate conditions in order to achieve a better yield.

Hybrid seeds are usually diverse in dry matter production and fiber digestibility. Finding high yielding seeds with above average dry matter digestibility and fiber will be helpful. Some hybrids have a gene leading to an increase in silage leaf content. High leaf area hybrids vary somewhat in characteristics, but usually perform close to or better than conventional hybrids and have softer seeds that dry more quickly. Some of these hybrids may have more starch and fiber than regular hybrids. For this purpose, respectable farmers can check the types of silage corn hybrid seeds produced by the Corn Cultivation Development Company and choose the right hybrid seed for their farm in consultation with the company's experts. Considering the possibility of the first crop or the second crop of this product, the appropriate planting date of silage corn will also be effective in the final yield. Although fodder corn responds well to early planting, it is more tolerant to late planting than grain corn.

Appropriate plant population will also have an effect on silage corn yield. In general, it is recommended that the density of silage corn should be 10-15% more than the density of seed corn. Therefore, the population for fodder corn should be 5,000 to 10,000 plants per hectare more than for seed corn. This often results in an optimal plant density level of 80,000 to 85,000 plants per hectare in most soils. If fertile soil is available, higher density is also recommended.

What are the effects of living and non-living stresses on fodder corn?

Sometimes forage corn is damaged or killed by cold before it reaches maturity. If the frost is premature and the green leaves remain on the plant, the crop will continue to accumulate dry matter and should remain in the field until the appropriate moisture is reached. Usually, frozen and immature plants have a lot of moisture and are not suitable for silage. These plants dry slowly and as the leaves fall in the field, the loss of dry matter increases. Therefore, if possible, it is best to dry the crop to an acceptable level in the field (at least 72% moisture for a horizontal silage), unless dry matter losses appear to be too high or harvest losses increase dramatically.

Drought stress can be one of the problems in corn silage production. If corn is under drought stress to such an extent that its growth may decrease rapidly, it is better to store it in silage. Corn in these conditions usually slows down its growth, its leaves turn brown and may fall off. If corn is drought stressed and has green leaves, it may grow late in the season and its dry matter content will increase. Therefore, it is better not to harvest prematurely. Corn generally has a little more moisture than it looks at this stage, so wait and delay harvesting. The net energy content of drought-stressed maize is usually less than 15% of normal and sometimes contains slightly more crude protein. The fodder obtained from drought-stressed forage corn often contains highly digestible fiber. Therefore, if some corn kernels are added to it, it makes an excellent fodder that can sustain milk production.

One concern with corn under drought stress is high nitrate levels in silage. Nitrate levels will be high when N is overfed or when corn is drought stressed and harvested after rain. For crops that you suspect have high nitrate levels, it's best to harvest them sooner, as the fermentation process reduces nitrates by up to 50%.

In addition, weeds also reduce the yield of fodder corn due to competition for nutrients and water. To reduce this competition, you can use herbicides. Also, having information about the history of weed presence in the field will be very useful in order to select the best herbicides.

Properly produced corn silage should have a yellowish-green color and a light, pleasant, slightly sour smell. If it is dark brown in color or has an incorrect odor such as fruity or burnt or pungent, improper fermentation or overheating may have occurred. Understanding the fermentation process can help explain some of the problems that may arise in silage production.

What is the fermentation process of corn silage?

When the corn plant is chopped and placed in the silo, the plant cells are still alive. These cells breathe together with the microorganisms inside the silo and produce carbon dioxide and heat. This process is known as aerobic respiration. As oxygen levels decrease and carbon dioxide levels increase, respiration slows and eventually stops, which is when anaerobic fermentation begins. In this process, beneficial bacteria use the carbohydrates dissolved in the cells and lactic acid is produced. This lactic acid reduces acidity (pH). Fermentation continues until sufficient lactic acid is produced and the pH drops to about 4.2. At this level of acidity, the activity of all bacteria ends. Typically, these conditions occur three weeks after filling the silo (see Figure 1). If the amount of lactic acid produced is low, an acid with an unpleasant smell called butyric acid is produced, and the silage is damaged and is not suitable for consumption.

The right harvest time is one of the most important factors that affect the quality of silage produced from corn. The amount of nutrients and moisture in the plant affects the quality of the silage during the corn harvesting stage. If the corn moisture is too high during silage, the silage may leak. This sap has a high concentration of nutrients (which should be produced in corn); But due to leakage, they move away from the corn and as a result, they are not beneficial for the silage. Also, leachate leakage can lead to significant damage in vertical silos. Also, in silage that has a lot of moisture, the time needed to produce lactic acid and its pH drop is longer. This problem reduces the quality of silage. On the other hand, if the silage suffers from a lack of moisture, the silage operation will not be performed well and aerobics will remain in the silage, which will prolong the period of aerobic to anaerobic conversion. The long period of aerobic conversion in silage leads to consumption of nutrients for protein, energy neutralization (respiration), reduction of silage quality, increase of temperature and even occurrence of silage fire. The suitable humidity for corn silage is at least 60% and at most 70%. In compartment silos, which are less compressible, a humidity near 70% would be more appropriate. But in wall silos, as well as in trench silos, which have the possibility of more compression, a humidity of about 60% will be more suitable. The grain milk line can be used as an approximate method for moisture estimation. In general, when the milky line is one-half to two-thirds of the way down the grain, wheat moisture is in the range of 60 to 70 percent.

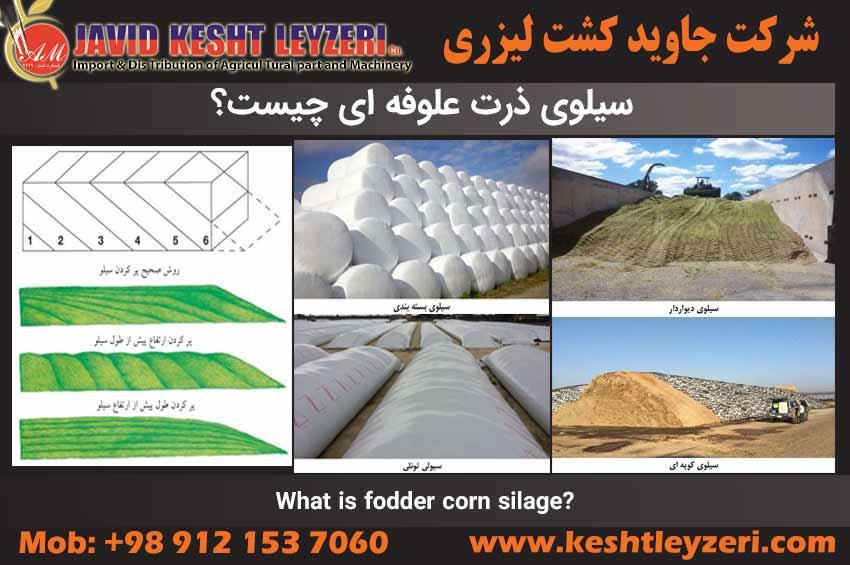

What are the types of corn silage?

In general, there are five types of silos, namely compartment silos, vertical silos, wall silos, trench silos, and tunnel silos. But recently, with the use of new packaging machines, the construction of closed silos is also done, which has significantly improved their production quality. But it should be noted that in our country, moat and walled samples are widely used.

How to preserve the quality of corn silage?

To maintain the best quality, fill the corn silage as quickly as possible and cover it well to reduce the air volume in the silage. Preventing air and water from entering the silo is very important to maintain the quality of the silage. It is better to cover the silo with suitable plastic and old elastics and pour soil on the side of the silo to drain the rainwater. The best way to fill the silo is the slant method, where the forage is continuously filled at an angle of 30-40 degrees. This method reduces the surface area, which can reduce the quality of the material and digestible food.

Chopping the silage into pieces of one to one and a half centimeters helps to fill the silo better. Depletion of maximum oxygen over time reduces the time required to start the anaerobic stage of fermentation. The faster the silo is filled, the faster the fermentation will start and the less losses and the better the silage quality will be. Therefore, the size of the silo is important, because the bigger the silo, the more silage it can hold and the longer it takes to fill.

What are the dimensions of the fodder silo?

The height of the silo should be a maximum of 5 meters and a minimum of 3 meters. In addition, the width of the silo should be twice the size of the loader or tractor that is used to compact the silo. Although, there is no limit to the length of the silo, but it is better to be so long that the silo can be filled in 2 to 3 days at most.

Also, to better estimate the dimensions of the silo, it is necessary to pay attention to several points. Is your silage trenched or walled? Since in these two types of silos there is a possibility of better compression, this is a very important point. In walled silos, the amount of dry matter storage is about 225 kg per cubic meter, while in silos without walls, this number is about 200 kg per cubic meter.

Also, on average, 15 tons of dry fodder (with 75% humidity) are harvested per hectare. As a result, approximately 67 cubic meters of space is needed for a walled silo and about 75 cubic meters for a wallless silo. To convert the silo volume to the required dimensions, just multiply the width, length and height together and determine the appropriate dimensions. For the mentioned example, it is necessary for a walled silo with approximate dimensions of width 6 meters, height 2 meters and length 6 meters.

Therefore, depending on the type of silo, amount of dry forage and yield, you can determine the dimensions of the silo for your farm or ranch.

What are additives to silage?

If the corresponding forage corn is properly ensiled, this will increase the level of carbohydrates and create a lot of lactic acid. But if conditions such as chopping or storage do not have ideal concentration, it may reduce the quality of forage. In such a situation, it is better to use additives in the silage to improve the fermentation process. Of course, you should note that additives are not a substitute for proper management in the fodder corn production process. Therefore, you still need to pay attention to factors such as moisture, crushing, packaging and other important factors when producing silage corn. In general, three types of compounds that can be added to corn silage include bacterial inoculations, application of acids, and non-protein nitrogen sources.

1- Inoculated bacteria

There are a large number of bacteria responsible for the production of lactic acid in the silage containing inoculum bacteria. When these bacteria are added to corn forage, the concentration of beneficial bacteria increases, resulting in a faster rate of lactic acid production and a faster decrease in pH. It is noteworthy that most of the inoculated bacteria do not help to improve the fermentation process of corn silage, because corn naturally contains a high concentration of this type of bacteria and soluble carbohydrates. However, adding bacteria can be beneficial under unfavorable conditions.

2- Acids

Preservative acids serve the purpose of preventing the accumulation of harmful molds and bacteria that will lead to improper fermentation. Some of the corn fodder normally does not need to consume these acids. However, using these acids in silos with high oxygen levels can be beneficial. In these cases, it is better to add these acids before covering the silage and help to reduce the spoilage of the silage. The use of buffer acids, which includes a type of weak acid and its salt, is the best solution to reduce damage to agricultural machinery.

3- Nitrogen and non-protein sources

The protein content of corn forage is significantly low, so adding non-protein nitrogen such as urea to silage can significantly improve the crude protein content of silage. Consuming corn forage as an ideal feed converts non-protein nitrogen to be added to it. Studies have shown that adding 5 kg of urea per ton of silage is the best way to use non-protein nitrogen in corn.