Technical report of the review of the straw press machine

javid keshtleyzeri Co.ltd

Experiment Report Summary:

-

YALÇIN Straw Baler:

- Manufactured by Yalçın Hidrolik Makina-Alattin YALÇIN.

- Portable machine with articulated suspension system.

- Can be powered by the tractor's stem or an electric motor.

- Features a feeding tank and a straw packaging system.

- Hybrid machine with rubber wheels and towing capability.

-

Introduction and Technical Specifications:

2.1. General Dimensions (Figure-1):

- Length (Transport mode): 4200 mm

- Length (Working mode): 4200 mm

- Width (Transport mode): 2400 mm

- Width (Working mode): 2400 mm

- Height (Transport mode): 3000 mm

- Height (Working mode): 3000 mm

- Weight: 5500 kg

- Color: Turquoise Orange

- Figure 1- YALÇIN straw press machine

2.2. Operation Principles:

- YALÇIN Straw Baler is powered by the tractor stem or an electric motor.

- Processes collected dry straw, stems, and weeds from farms.

- Utilizes a helix conveyor to transport materials to the feeding tank.

- Compresses straw using a feeding cylinder and packages it with a packaging cylinder.

- Packaged straw is conveyed on a belt for transportation.

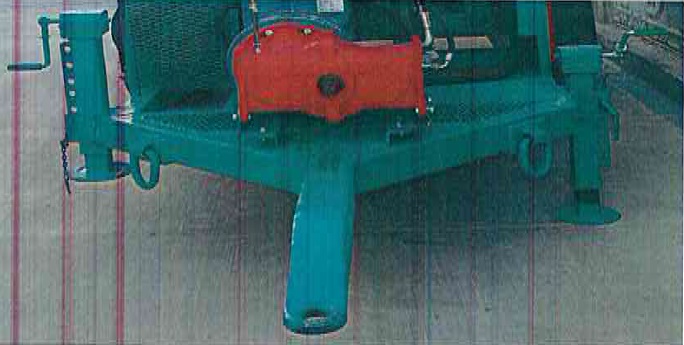

2.3. Motion Transmission System (Figure-2a-b):

- Movement from the tractor's stem to the baler and hydraulic pump.

- Hydraulic pump volume: 105 cc.

- Generator provides electrical power for the system.

- Radiator, compressor, helices, and conveyors are belt-driven.

-

- Figure 2-3 transmission system of straw press machine

2.4. Feeding Tank (Figure-3):

- Inverted pyramid-shaped tank made of 3mm sheet metal.

- Equipped with a clip for adjusting and controlling the feed amount.

- Feed tank volume: 500 cubic meters.

-

Figure 4- Feeding tank of the straw press machine

-

2.5. Straw Packaging Equipment (Figure-4a-4b):

- Utilizes a feeding cylinder to compress straw.

- Packaging cylinder packs and conveys the compressed product.

- Allows manual or automated plastic bag packaging.

- Weight adjustments for packaging are possible.

-

Figure 5 and 6: Straw press machine equipment

-

2.6. Chassis and Towing Gear (Figure-6):

- Main chassis made of two 80x120x5 mm profiles.

- Front roof section has two V-shaped 80x120x5 mm profiles with a towing gear.

- Towing gear includes adjustable cylindrical bases with or without gears.

- The towing ring is fixed to the towing gear.

2.7. Axle:

- Prevents 90-degree collisions with two short shafts.

- Equipped with wheels using bearings in the axle.

Figure 6: Chassis and gear of the straw press machine

Dimensions and Wheel Specifications:

Nominal Wheel Dimensions: 400/60-15.5 Track Width (Is): 1900 mm Tractor Type: New Holland TD 110D

Safety Equipment: This machine is equipped with a set of safety equipment to prevent breakage, cracking, and similar issues resulting from high stress during operation. The connecting shafts used have a safety system to prevent excessive stress.

3. Test Method: Sound tests were conducted based on the TS ISO 5131 standard, and other tests were classified according to our testing methods (Müdürlüğümüz Deney Yöntemlerine).

4. Test Conditions and Results:

4.1. Test Conditions:

- Tractor Used:

- Tractor PTO Speed: 513 RPM

- Materials Used:

- Straw

- Moisture Content of Straw:

- 5%

- Field Slope:

- Flat

4.2. Test Results (Figure-7):

Table 1: Efficiency

Figure 7: Straw press machine

| Package Size | Bag Weight (mm) | Bag Weight (kg) | Efficiency (Bags per hour) | Efficiency (Tons per hour) |

|---|---|---|---|---|

| 800x400 | 30 | 6 | 198 | 0.06 |

Table 2: Sound Tests (When Using the Electric Motor)

| Machine Operating State | Sound Level (dB A) |

|---|---|

| Empty | 76.7 |

| Idle | 84.5 |

Table 3: Tractor Milling Force Requirements

| State | PTO 540 RPM | Torque (Newton-meter) | Power (Punching Fingers/kilowatts) |

|---|---|---|---|

| Empty | 181 | 13.01/9.7 | |

| Idle | 318 | 22.8/17 |

*Efficiency depends on material density and operator skills. *Packaging weight is also related to material compaction.

4.3. Device Observations: During the laboratory observations on the device, the following points were noted:

- Adequate safety features in moving parts.

- Easy preparation of the device for operation.

- Observations during device operation:

- Vibration-free operation under normal conditions.

- No blockages in the equipment.

- No excess heat observed in the carrier area.

- Adequate safety in moving parts of the device.

5. Corrections Made During the Test Period: No corrections were made during the test period.

6. Recommendations: No recommendations have been provided.

7. Conclusion: Based on the test results on the YALÇIN Baler machine produced by Yalçın Hidrolik Makina-Alattin YALÇIN, capable of operating with the tractor stem or an electric motor, it appears to be suitable for agricultural technology.

Note: This report is only valid for this sample. A request is strongly recommended for retesting and reviewing the information following the provided suggestions. In case of non-compliance, the issued test report will be considered invalid. This report is subject to the sales settings and does not fall under the machinery safety regulations (2006/42/EC). This report will not be reproduced without written consent from TAMTEST, except for specified cases. This report was conducted between 19.11.2020 and 24.11.2020. This report is valid for 5 years (24.11.2020-24.11.) All this report was received from YALÇIN straw baler manufacturer website.