Increasing the quality of produced corn silage

javid keshtleyzeri Co.ltd

Fodder corn is one of the strategic inputs in the livestock industry. Several factors, including controllable managerial factors and uncontrollable environmental factors, affect the quality of fodder. Harvesting time has an effect on the quantitative and qualitative yield of corn silage. As the plant ages, there is a big change in its palatability and digestibility at the time of harvest. By using the right cultivars for each region and determining the right harvest time, it is possible to obtain the maximum production and yield both quantitatively and qualitatively, palatability and nutritional value of fodder. The late harvest of corn has increased the quantitative yield, while the quality of the fodder decreases as the plant's growth period approaches. Unfortunately, due to the prevailing conditions in the corn fodder market and the high importance of production tonnage in the profitability of the silage production industry, general farmers tend to increase production a little and pay less attention to the quality of fodder production. It is worth noting that this process has been obsolete for years in advanced countries, and in buying fodder, not only the tonnage, but also the analysis of the quality of the produced fodder in terms of energy, fiber and other characteristics is very effective in the final price. Considering the direct effect of fodder quality on the amount of milk and meat produced in livestock farms, it is necessary to gradually pay more attention to the quality of fodder produced by respectable farmers and ranchers.

A) Harvesting time of fodder corn

When the right time for fodder corn arrives, it is necessary to check the field regularly. The internal rows of the product (at least 15 to 20 rows inside the farm) should be examined to ensure the handling conditions of the product. What is necessary to ensure the handling of the product in question is as follows.

1- Plant color:

The entire plant will normally still be green (unless damaged by moisture stress or freezing). The cob coat changes color while the rest of the plant is still green.

2- Seed processing:

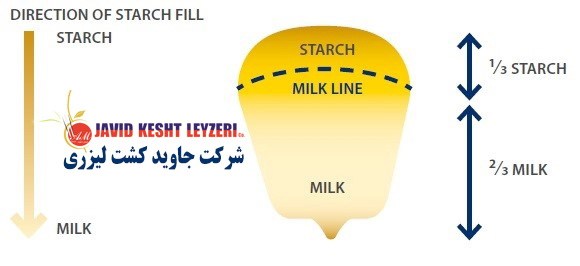

As corn kernels approach maturity, plants collect water-soluble carbohydrates (sugars) from leaves and stems to store starch in the kernel. Starch first accumulates in the outer part of the seed (closest to the inner shell). As the grain ripens, starch starts to fill from the outside to the inside of the grain. The milky line is the junction between the hard starch and the milky and soft endosperm. Monitoring the grain milk line is a useful guide to approximate ripening conditions. It is worth noting that the dry matter percentage of the whole plant cannot be determined using the position of the milky line of the seed alone. Because the date of planting, climate and the difference between different cultivars cause a change in the amount of dry matter of the plant according to the position of the milk line. Therefore, the position of the milky line of the seed is the only guide for harvesting the crop. Of course, the main and accurate standard will be to determine the moisture content of the whole plant to evaluate its dry matter content.

3- Evaluation of the milk line of the seed:

Choose a number of cobs from different places in the field. Peel the cobs and cut them in half. Take the tip of the cob towards the ground and check. To evaluate the milk line, determine the position of the milk line using the tip of a pen or a nail.

4- Evaluation of the dry matter percentage of the whole plant:

Determining the dry month percentage of the plant is the best way to ensure the right harvest time. For this purpose, select and harvest a number of bushes randomly from at least 15 to 20 rows inside the field. Use a garden shredder to check the humidity level of the bushes. Mix the chopped plants well and send two or three large handfuls of the chopped material to the laboratory for analysis of dry matter percentage.

5- percentage of dry matter by squeezing chopped corn:

It should be noted that this test is not a substitute for evaluating the dry matter percentage of chopped corn through laboratory methods. But it can create an estimate of the percentage of dry matter. For this purpose, squeeze a large handful of chopped corn in your hands for 1-2 minutes and roll it into a ball. Then quickly open your hand and examine the cornball:

Dry matter less than 25%: if it keeps its shape and plant sap flows from the fingers. Moisture is high and postpone harvest.

Dry matter between 25 and 30%: the corn ball keeps its shape, plant juice flows a little, the moisture is felt on the hand. Delay harvest, or chop corn to 15-20mm.

Dry matter between 30 and 40%: the corn ball slowly loses its shape and collapses. The hands are only moistened and the herbal juice does not flow. Start the withdrawal.

Dry matter more than 40%: Corn pellets are dry and crumble and fall apart quickly. Fingers are also dry in contact with it. Harvesting is late, harvest quickly and to improve the density of fodder packing, it is better to chop it in 5-9 mm size.

Evaluation of milky line in corn kernels

Milk in half a grain

· In the phase of accumulation of dry matter

· About 30 to 35 percent of dry matter

· Need for detailed investigation

· 7 to 10 days before harvest, especially if quality is a priority.

· Checking the color of the sheath and testing the dry matter

Milky line in one third of the grain

· In the phase of accumulation of dry matter

· Need to wait and check more

· Check the amount of dry matter again in one to two weeks.

Black Point

About 40 percent of dry matter

· Too dry for a good silage

Late withdrawal, as soon as possible

· Make the length of the cut pieces shorter

· Focus on good grain processing into silage

Milky line in two thirds of the grain

In the stage of accumulation of dry matter

About 35-38% dry matter

Checking the color of the sheath and testing the dry matter

Withdraw as soon as possible.

It is better to chop cob wood into pieces smaller than the size of the little finger, larger pieces will cause problems for air to escape from the silo. To check the crushing process of seeds, pour a sample of silage in a bucket of water and give it time. In this way, the seeds go down and the wood pieces of cobs and vegetables remain on the water. Empty the water in the bucket so that the seeds remain in the bucket for better inspection. Arrange the chopped ingredients.

Processing percentage of the seeds: It is better if the seeds are completely broken and not just scratched.

The percentage of seeds that are processed correctly: it is better that more than 90% of the seeds are broken and the minimum amount of healthy seeds is observed.

Theoretical standard of chopped corn size in terms of percentage of dry matter

Size of chopped corn, dry matter percentage

10-15 mm dry matter between 32 and 38%

15-20 mm dry matter less than 30%

5-9 mm dry matter more than 40%

b) percentage of dry matter during harvesting

The decision on when to harvest depends on a balance between the quality and quantity of harvested forage.

Harvesting at the last possible time and achieving the maximum yield and the highest amount of dry matter in the silage

Harvest before the entire plant is too dry or too mature to harvest a quality silage

The target dry matter percentage is a compromise between obtaining the best possible yield per hectare and having excellent quality silage for livestock. Because the best percentage of dry matter is between 32 and 38 percent (or 62 to 68 percent moisture). For the first day of harvesting, start harvesting at the lowest dry matter percentage (32%). Because the percentage of dry matter can increase by 1% every 2 to 3 days depending on weather conditions.

Corn silage that is too wet (dry matter less than 30%):

The effective loss of nutrients from silage in the form of effluent is among the damages caused by silage of fodder corn with high humidity, and if the effluent reaches waterways, it causes environmental concerns.

In this case, the reduction of dry matter is likely to be effective and the final percentage of dry matter in the silo will be lower than the target value (32 to 38%).

Reduction of sugar and protein: Effluent contains nutrients that are soluble in water, which reduces quality and essential materials in silage. As a result, the produced silage will have less energy.

Wet corn produces too much acid and lowers the pH of the environment. This may cause livestock to refuse to feed on silage.

Acetic acid (vinegar) is produced in corn silage with high humidity. Cows accept the taste of vinegar to some extent, but too much vinegar will make the feed mixture tasteless and will also cause metabolic side effects.

Too dry silage (dry matter more than 40%):

Too little moisture in corn forage may cause corn leaves to break during harvest and forage collection. In addition, it will be difficult to chop, collect and silage too dry fodder. In such silage, it is less possible to release air and the fermentation process is prolonged and the pH of the environment reaches the final level later. In this case, more soluble nutrients are consumed. All these materials lead to a decrease in the dry matter of the produced silage, while the aerobic stability of the silage is reduced when it is removed from the silo (or bag) and the environment is prepared for heating and spoilage of the product.

c) The composition ratio of ingredients in corn silage

The type of fodder corn variety and management factors affect the final quality of corn silage. Examples of factors that change quality include:

The ratio of corn greenness to corn kernels

Green quality of corn and corn kernels

1- The ratio of corn greens to corn seeds:

Corn silage is a combination of different parts of the corn plant. This composition contains vegetables including the stem, leaves, pods that cover the cob, and the wood of the cob that holds the corn seed and finally the corn seed.

The combination of corn kernels and corn greens is a very good source of starch, along with a lot of effective fiber for feeding ruminant species such as cattle, sheep, goats and deer. Corn kernels are an energy-dense and starch-rich feed that complements the low quality of the bulk and filling vegetable.

Analysis sample of harvested corn seeds and vegetables with 35% dry matter

Vegetable seeds food content

9.5 6.5% neutral insoluble fiber

14.5 8.5 energy (megajoules of absorbable energy per kilogram of dry matter)

78.0 0 percent of starch

2- Quality of green corn and corn seed and its effect on corn silage:

Vegetables consist of stems, leaves, cob husks and cob wood, and are of lower quality than corn seeds. The vegetable does not contain starch and has water-soluble carbohydrates, low protein and high fiber or neutral insoluble fiber (NDF). As the corn plant matures, the quality of the greens decreases. At that time, the percentage of dry matter of the whole plant reaches 40-42% or more, the content of fiber and lignin increased (so the digestibility of insoluble fiber decreases), the content of water-soluble carbohydrates and absorbable energy per kilogram of dry matter ( MJME/kgDM) is lower than younger plants. The quality of corn kernels is very high compared to corn greens. Due to its high starch and low fiber (neutral insoluble fiber), corn kernels have a large amount of absorbable energy per kilogram of dry matter. As the corn plant matures, starch accumulation increases, until the plant reaches physiological maturity (black line or black layer). With the start of the drying process of the plant, the digestibility of starch also decreases. Like its vegetable, corn kernels have a low protein content and usually contain less than 10% of dry matter. By increasing the ratio of grain to vegetable in corn silage, the quality of corn silage improves.

The effect of different ratios of corn kernels to vegetables on the amount of effective substances in the quality of corn fodder

Energy (megajoules of energy per kilogram of dry matter), fiber percentage, starch percentage, grain percentage, vegetable percentage

10.3 48.4 23.4 30 70

10.6 45.6 27.3 35 65

10.9 42.8 31.2 40 60

11.2 40.0 35.1 45 55

11.5 37.3 39.0 50 50

d) Incorporating corn silage into livestock diets

Regarding the introduction of corn silage into the livestock diet, there are two main aspects that should be considered when starting to use corn silage for the first time:

Silage habituation: behavioral adaptation of cows or heifers that have not been given corn silage before.

Rumen Adaptation: The microbial population required to regulate digestion of new feed and ensure optimal feed digestion.

1- Getting used to feeding corn silage:

Young cows and growing two-year-old heifers need more time to adjust to this feed than older cows who are more familiar with feeding corn silage. It is better to accustom heifers to corn silage feed a few weeks before calving. In this way, the heifers get used to corn feed during and after giving birth and consume it easily.

2- Ruminal habituation:

The rumen microbial flora in animals that use starch is different from the type that uses fresh forage. It takes approximately 10-14 days for the microbial population suitable for digesting fresh forage to change to a population suitable for starch digestion. A sudden change in starchy diets may increase the risk of ruminal acidosis. This risk depends on the ratio of corn silage to the total diet and the level of total dietary fiber (NDF), as well as the presence of other starch-containing feeds in the diet.

e) A look at common fodder corn cultivars in Iran

For a long time, variety 704 has been used for planting fodder corn and has become common throughout the country. The 704 variety is actually "grain" but due to the cheapness of the seed and the support of the seed and government support, it has been able to occupy the largest area under cultivation in the planting of grain corn and fodder corn in the country. Basically, the reason for its popularity is Due to the absence of competitors and the belief of farmers and breeders in its production, what has settled among them is the high production efficiency per hectare, the palatability of its silage for cattle and sheep, the possibility of planting as a spring crop (the first crop) and the second crop after It has been from harvesting barley or wheat and occupying less storage space compared to other available fodder, but these advantages can be found today even with better conditions in special fodder and modified varieties, so that in addition to the mentioned advantages, the ability The breakdown of some non-nutritive substances into nutrients during silage processing is in more optimal conditions than the old variety 704, and in general, they have better digestibility for consuming animals.

The variety 704 is actually a late variety that is more suitable for the first crop than the second crop, because in most cases, the time of harvesting the second crop coincides with the beginning of the autumn rains, and the farmer, fearing that the fodder will remain in the field, harvests it at the end of September. And he does it in early October.

Today, due to the efforts of the Corn Cultivation Development Company, there are competitors for 704 corn in the country, whose biggest advantages compared to the mentioned variety are in maintaining the greenness of the plant, which increases the dry matter of fodder to 30 and even 35 percent. It has been proven experimentally that after the increase of dry matter from about 26 to 28%, the leaves and stems under the cob, which are the heavy part of the biomass, started to dry up completely, and at 30% dry matter They become dry and woody and indigestible. For this reason, if we pay attention to the 704 type silage that has been ensiled with more than 28% dry matter, most of the time the seeds are hard and unusable and the fodder is not crushed well in ground silos. To solve this problem, it is recommended that the chopper device Set to harvest at least 70 cm above the ground. This itself causes a high deviation in silage production.

The new cultivars introduced to the country's farmers by the Corn Cultivation Development Company are more productive in the field in terms of quantity (production tonnage) and quality (production of high-quality corn silage). These cultivars are usually divided into three groups: medium-ripening, early-ripening and semi-late-ripening. Like variety 704, whose mother seed has been produced and supplied in Iran for about 40 years, it is appropriate that the plant breeding experts of the country should take care in localizing the good foreign variety. They are introduced as examples:

1- Valbom single cross hybrid:

From the late group, rapid germination and growth, maintaining greenness until the ears reach maturity, good adaptation to different weather conditions of the country, suitable for sandy and loamy soils.

2- Hybrid single cross Simon:

From the middle-ripening group, it has large and deep quality seeds, good for livestock (due to the high amount of soluble sugar in the stem and leaves as well as in the seeds). More seed production and higher seed volume per hectare, extensive adaptation to different climatic conditions, tall plant height and having strong stems, cob formation in the lower nodes of the stem, resistant to plant dormancy.

3- Hybrid Single Cross BC678:

From the mid-ripening group, the leaves and stems are suitable for fodder production, the stems are strong and long, the ears are large, the greenness of the plant is maintained until the ear reaches maturity, the high performance of this variety in different climates.

Corn silage

Maize Cultivation Development Company uses modern fodder packaging machines to store some of the corn fodder produced by farmers in 500 kg, 30 kg packages and tunnel silos and supply it to the consumer market every year. One of the important benefits of silage production is that the harvested fodder is immediately packed and aerobic fermentation and food waste in fresh silage are avoided. The main factors affecting the quality of corn silage are as follows:

Factor in the usual rate of interpretation

pH 3.7 - 4.2. A pH above 4.0 is usually due to a high amount of DM. This high value sometimes also indicates that the fodder corn silage has been exposed to a large amount of air.

Ammonia NA 5-7 The high amount of this factor is the result of the high rate of protein breakdown. Keep in mind that corn silage has a low crude protein content (about 8%).

Lactic acid (based on % DM) 4-7 The high value of lactic acid concentration indicates that the silage has been properly stored. If the amount of lactic acid is low, it shows us that the fermentation process is not done properly and the reason for this can be high DM or seriously exposed to air.

Acetic acid (based on % DM) 1-3 A high concentration of acetic acid usually indicates that the silage was very wet or had improper packing. However, a high amount of acetic acid does not always indicate improper silage storage, and this issue should be carefully considered.

Next, by clicking on the image below, you can see the images of the fodder packaging machine:

Delivery and commissioning of 800 to 1200 kg fodder packaging machine Komel - Dezful