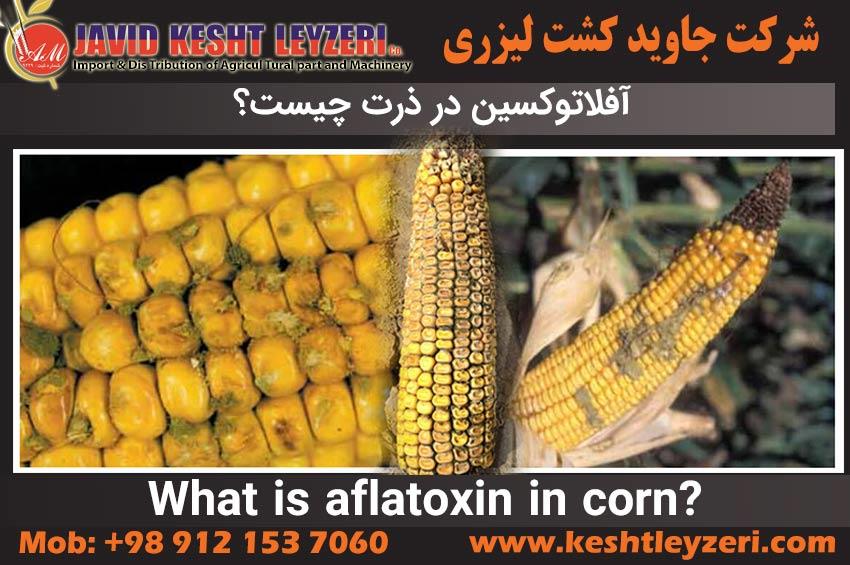

What is aflatoxin in corn?

javid keshtleyzeri Co.ltd

Poisons called aflatoxins are harmful and even fatal for livestock and poultry and can cause cancer for humans and animals. Higher amounts of aflatoxin are more common in hot and dry seasons. The main conditions for the production of this toxin by the fungus are warm nights with temperatures above 20 degrees Celsius in the final stages of seed growth and in the drying phase. In years of potential risk, it is necessary to screen for aflatoxin in grain drying plants or when corn is released to the market. Field or warehouse performance tests may help to determine the presence of aflatoxin, but the results of these tests only give a relative indication of the amount of aflatoxin. This is due to the fact that toxins are produced inside corn kernels and only by using specific analytical tests can their presence be determined. Also, the amount of aflatoxin per grain may vary greatly. Therefore, the correct sampling of the seed mass is an important step for the actual determination of aflatoxin levels.

How is corn sampling for aflatoxin testing?

Considering that aflatoxin usually occurs non-uniformly in the corn seed mass and is present in small places, the best method to prepare a sample is a combination of small samples of the corn seed mass. The suggested method for this purpose is to collect small samples in a rotating manner. Using this method, at least one composite sample with an approximate weight of 5 kg is obtained. Another option is to collect samples from every 5 levels of 1 grain unit (assuming the length of each grain unit is about 2 meters) plus 1 sample from the center of the grain unit in the warehouse. It is better to collect your community sample from different parts of a separate plot. Fields that differ in cultivation history, tillage methods, planting date, soil type, and hybrid type may also differ in susceptibility to aflatoxin. A minimum of 10 to a maximum of 30 sampling points per farm is required. For approximately every 2 hectares of field, between 3 and 5 kg of samples are collected and then quickly dried to 12-14% moisture to prevent aflatoxin production during transport. Samples with high moisture content should be frozen and sent to the laboratory frozen. Dried samples are best stored in cloth bags.

What are the regulations regarding aflatoxin in corn?

According to the National Standard No. 5925, the Iranian Standard and Industrial Research Institute has determined the maximum level of aflatoxin in corn to be 30 ppb. If corn is used as animal and poultry feed, aflatoxin levels must be below 20 ppb. On the other hand, the US Food and Drug Administration (FDA) has set a maximum level of 20 ppb (1 per billion) for aflatoxin for interstate corn commerce. If this limit is exceeded, regulatory measures will be taken, such as stopping the sale or banning the sale of corn. Therefore, corn dryers should not accept corn with a level of 20 ppb or higher unless there is a specific use for which a specific level of aflatoxin is permitted. Thus, even one contaminated grain in a 3 kg sample may cause aflatoxin levels to rise above 20 ppb. The US Food and Drug Administration has developed guidelines for the use of contaminated seeds in animal and poultry feed (Table 1). These guidelines have been compiled in order to preserve the value of the seed and prevent the occurrence of diseases caused by aflatoxin. It should be noted that the consumption of contaminated seeds is prohibited for lactating cows, where prevention of aflatoxin residues in milk is very important.

What are the consequences of high concentration of aflatoxin in corn?

Aflatoxins are very potent compounds that can cause various health problems in humans and animals. In some rare cases, feed contaminated with aflatoxin may cause animal death. The common side effects of aflatoxin in animal feed include reduction of feed efficiency and animal reproduction. This compound may suppress the animal's immune system and cause an increase in infectious diseases. It is of great concern that aflatoxin B1, which is the most widespread type of aflatoxin, has carcinogenic properties. This is why the use of milk from lactating cows that have been fed with contaminated corn is a concern for human health.

How to avoid aflatoxin in corn?

If the right conditions for aflatoxin production are present, it is very difficult to prevent contamination. Therefore, a realistic goal is to minimize pre-harvest contamination by proper agronomic practices and minimize post-harvest contamination by careful care and storage. In general, problems related to Aspergillus and aflatoxin are common in hot and dry years. The fungus survives in crop residues and soil and produces abundant spores during the growing season. Maize contamination by Aspergillus fungus, as well as pests and diseases caused by it, occurs in hot (above 30°C) and dry conditions during the growing season of the fungus. Yellow and brown cockles are more susceptible to infection. Insects, hail, drought stress and early frost damage the seeds and spread the fungus inside the cob. Aflatoxin is a secondary metabolite produced by Aspergillus under certain conditions. Dryness and high temperature (25 to 40°C) during seed filling are the most common factors affecting aflatoxin production before harvest. Warm nights (above 21°C) may also increase the risk of aflatoxin contamination. The production of poison depends on the humidity and temperature of the seeds. The highest amount of poison in seed moisture is about 18-20% and stops at about 15% seed moisture.

Aflatoxin causes many problems during grain storage. These problems start from the moment the grain enters the combine tank, and at that moment, the quality of the grain is at its best. The humidity of the stored seeds and the relative humidity of the air have a significant effect on the growth of mold and seed spoilage. The moisture content of the stored seeds determines the relative humidity of the air around the seed. High humidity in the grain leads to an increase in the relative humidity of the air around it, and molds grow rapidly in conditions of high relative humidity. But during storage with low humidity, the air in the storage chamber is controlled with lower relative humidity and grain spoilage due to mold growth. The best way to control mold growth in stored grain is to use grain with a low moisture content. A safe moisture level for corn storage is approximately 12-13%, and for long-term storage it should be around 12%. Also, placing wet grain loads next to low moisture grain loads limits the safe storage time of the entire warehouse. Research has shown that even when wet and dry seeds are carefully mixed to allow moisture, a moisture difference of 2% between seeds may remain. Also, if the seeds are not mixed properly, this difference will be much more and it will reduce its life.

The following methods can reduce the risk of aflatoxin contamination in grain:

Consumption

Maximum tolerance of aflatoxin according to the Iranian Standard Institute

Maximum tolerance level of aflatoxin

According to the FDA

Grain corn generally less than 20 ppb less than 20 ppb

Corn in young animal diets less than 20 ppb less than 20 ppb

Corn in dairy feed less than 20 ppb less than 20 ppb

Corn in light livestock and poultry diets less than 20 ppb less than 100 ppb

Corn in heavy animal ration ready for slaughter less than 20 ppb less than 300 ppb

What are the consequences of high concentration of aflatoxin in corn?

Aflatoxins are very potent compounds that can cause various health problems in humans and animals. In some rare cases, livestock may die from eating feed contaminated with aflatoxin. One of the common consequences of aflatoxin in animal nutrition is the reduction of feed efficiency and reproduction. This substance may suppress the animal's immune system and cause more infectious diseases. Unfortunately, aflatoxin B1, which is the most abundant type of aflatoxin, is carcinogenic. This has raised concerns about human health, especially when milk from dairy cows fed contaminated corn is used.

What is the way to prevent aflatoxin in corn?

If the right conditions for aflatoxin production are present, it is very difficult to prevent contamination. Therefore, a realistic goal is to minimize pre-harvest contamination by proper agronomic practices and minimize post-harvest contamination by careful care and storage. In general, problems related to Aspergillus and aflatoxin are common in hot and dry years. The fungus survives in crop residues and soil and produces abundant spores during the growing season. Maize contamination by Aspergillus fungus and its related pests and diseases occurs in hot (more than 30°C) and dry conditions during the growing season of the fungus. Yellow and brown cockles are more susceptible to infection. Insects, hail, drought stress and early frost expose the seeds to infection and help the fungus spread inside the cob... Aflatoxin is a secondary metabolite produced by the Aspergillus fungus under certain conditions. Dryness and high temperature (25 to 40°C) during seed filling are the most common factors affecting aflatoxin production before harvest. Warm nights (over 21°C) may also increase the risk of aflatoxin contamination. The production of poison depends on the humidity and temperature of the seeds. The highest amount of toxin in seed moisture is 20-18% and decreases in minimum seed moisture (8-10%). Therefore, controlling seed moisture during the growing season and after harvest is very important. Also, the temperature of the seeds should be kept in the appropriate range (15 to 20 degrees Celsius) to prevent the production of aflatoxin.

To control aflatoxin before harvest, the following methods can be used:

1. Use of Aspergillus-resistant breeds: The use of early-maturing breeds resistant to Aspergillus infection can help reduce aflatoxin before harvest.

2. Using physical methods: using heat drying of seeds, gathering seeds in cool and dry times, and using new technologies such as plasma processes and microwaves can help reduce aflatoxin before harvest.

3. Use of chemical methods: The use of antifungal agents such as antibiotics and chemical agents such as sorbic acid, calcium propionate and terbinafine can help reduce aflatoxin before harvest.

For post-harvest aflatoxin control, careful care and proper storage of seeds is very important. The humidity of seeds during storage should be around 12 to 14%. Also, the seeds should be stored in cool and dry conditions to prevent the production of latex after harvest. Also, the use of physical methods such as drying seeds with heat, collecting seeds in cool and dry times, and using new technologies such as plasma and microwave processes can also help to reduce aflatoxin after harvest. Also, the use of chemical methods such as the use of antifungal agents and chemical agents such as sorbic acid, calcium propionate and terbinafine can also help to reduce aflatoxin after harvest.

Aflatoxin problems during grain storage begin from the moment the grain enters the combine tank. At this moment, the quality of the seed is at its best. The humidity of the stored seeds and the relative humidity of the air affect the growth of mold and seed spoilage. The amount of seed moisture determines the relative humidity of the air. The high humidity of the grain leads to high relative humidity in the air around the grain and causes the high growth rate of molds. If grain is stored at low humidity, storage air with low relative humidity will control grain spoilage due to mold growth. In addition, the load of wet grain next to the load of dry grain limits the safe storage time of the entire warehouse. Research has shown that even when wet and dry seeds are carefully mixed to allow moisture, a 2% difference in moisture remains between the seeds. If the seeds are not accurately mixed, this difference will be much greater and will reduce the shelf life of the seed. In order to prevent cob rot and its storage problems, early detection of infected cobs in the field and in the warehouse is very important. The following methods can reduce the risk of aflatoxin contamination in the seed:

1. Proper storage of seeds: Seeds must be stored in proper conditions to prevent aflatoxin contamination. This includes keeping at the right temperature, controlled humidity and avoiding contact with moisture and insects.

2. Use of insecticide products: Using approved insecticide products and following the instructions for use can help reduce the risk of aflatoxin in seeds.

3. Check the product before buying: Before buying seeds, it is better to check them and detect any signs of aflatoxin or corrosion.

4. Use of post-vector technology: By using post-vector technology, you may be able to reduce the risk of aflatoxin. This technology involves the use of techniques such as cleaning, drying and disinfecting the seeds.

5. Observance of sanitary conditions in storage and transportation: during storage and transportation of seeds, sanitary conditions must be observed. This includes using the right packaging, handling at the right temperature and avoiding contact with contaminated materials.

6. Reporter tests: Before using the seeds, you can send them to a reporter laboratory for aflatoxin testing. This may help you identify the risks of aflatoxin in seeds.

7. Refine the grain: By refining the grain, you may be able to remove aflatoxin from the grain and reduce the risk of aflatoxin. This includes the use of techniques such as separation, filtration and the use of aflatoxin absorbing materials.

..8. Education of farmers: Education of farmers on the correct methods of cultivation, storage and protection of seeds can help reduce the risk of aflatoxin in crops. This includes training on the correct use of insecticides, storage at appropriate temperatures and avoiding contact with moisture.

9. Checking water sources: Water sources should be checked before being used to irrigate seeds to ensure that the water is not contaminated and does not transfer the risk of aflatoxin to the seeds.

10. Monitoring and inspection: Regular monitoring and inspection of seeds and crops can help in early detection of aflatoxin and take necessary measures to control it.

It is possible to control insects in the field and prevent pests and diseases by the second generation of European earworms and corn earworms. In order to control and prevent serious losses, timely monitoring and diagnosis is necessary. Check for Aspergillus rot by observing the cobs at 5 to 10 points in the field, from the corn tooth stage until harvest. Target ears are visible in stressed plants. At each point, peel 10 ears and check for olive-green powdery mildew. If more than 10% of the cobs show signs of Aspergillus rot, it is best to remove the corn from the field early. If you harvest the corn early, do sampling using the top grain sampling method and send the samples to the laboratory to determine the percentage of aflatoxin. Doubtful corn should be kept in a separate warehouse until the result is determined. Then, according to the aflatoxin level and using Table 1, determine the different uses of corn. If harvested early, corn must be dried and cooled quickly to prevent further toxin development. Also, adjust the combine carefully to minimize damage to the seeds. Fungi infect damaged corn more easily than healthy corn

After harvest, corn can be kept at 16 or 17 percent moisture in the winter and still remain clean and healthy. But moldy corn must be dried quickly to 15 percent moisture or less, because keeping the kernels moist even for a short time can cause significant mold and aflatoxin growth. For long-term summer storage, all particles should be dried to a moisture content of 14% or less. Moldy particles are not suitable for long-term storage. After drying, it is better to keep the seeds at a temperature between 10 and 15 degrees Celsius. Of course, it will be difficult to control the temperature when harvesting with a large volume and a huge mass of seeds. Aeration can control both temperature and humidity. Humidity control, along with temperature control, is an important factor in preventing pollution and toxins. Storage warehouse insects should also be controlled. Every two weeks, inspect the particles in storage for temperature changes, scaling, hot spots, moisture, and decay. If you see these conditions, you should immediately reduce the temperature, ventilate the warehouse and remove the contaminated seeds. You can use anti-fungal products to reduce the growth of mold in the warehouse. These products, such as propionic acid, are not able to destroy mold or reduce the toxins formed, but since moldy corn is not suitable for long-term storage, anti-fungal products can be used to prevent mold growth in storage. These products are not able to destroy mold or reduce the toxins formed, but you can control mold growth by using them. Also, storage warehouse insects should be controlled to prevent contamination and toxins. Every two weeks, the warehouse should be checked for temperature changes, scaling, hot spots, moisture and decay. If any such conditions are observed, the temperature should be reduced immediately, the storage should be improved, and the infected seeds should be removed.

What to do with corn contaminated with aflatoxin?

The use of a gravity device for seed cleaning and screening may lead to a decrease in aflatoxin concentration by removing the largest amount of contaminated particles. But, this method is expensive and it is not predictable how much the amount of aflatoxin will be reduced. In some cases, cleaning results in little reduction in aflatoxin levels. Also, the seeds from the cleaning process should not be used as animal and poultry feed.

Is it correct to feed livestock and poultry with grains contaminated with aflatoxin?

In the United States, aflatoxin-contaminated seeds may be used for animal feed. According to the guidelines shown in Table 1, if there is a discount on the sale of contaminated corn, livestock producers may be inclined to use contaminated corn with a concentration of less than 300 ppb. But in Iran, the standards are much stricter and corn with a concentration of more than 20 ppb of aflatoxin cannot be used in animal and poultry feed. Of course, for this purpose, it is necessary to have an accurate amount of aflatoxin in the seeds so that decisions can be made about animal feeding. Also, it is necessary to avoid mixing aflatoxin-contaminated seeds with healthy seeds for feeding animals. The use of corn silage does not usually result in a reduction in aflatoxin concentrations, although with proper management, the likelihood of increased concentrations in silage is low.

How is the production of ethanol from the wet milling method?

Corn contaminated with aflatoxin can be used to produce ethanol. Aflatoxins do not accumulate in ethanol, but concentrate in byproducts. In wet milling processing, aflatoxin accumulates in the gluten byproduct. A rough estimate shows that the level of aflatoxin in the final product will be up to three times the level in the initial feed. Therefore, producers who are sensitive to the presence of aflatoxin, such as milk, cannot use contaminated corn. It is better to look for the corn product with the least amount of contamination.