Characteristics of corn silage as the king of silage

javid keshtleyzeri Co.ltd

What is silage?

Silage can be divided into the fodder category based on the origin of the feed. Silage is produced and processed from the controlled fermentation of wet products such as corn fodder, barley, sorghum, alfalfa and clover, and it is considered an unparalleled feed for all types of livestock. With the help of fermentation, this feed is stored for a longer period of time and contains useful energy-generating substances to strengthen livestock. The key factor in preparing suitable silage is the high production of lactic acid in a short time and the rapid reduction of PH in silage fodder. Research results show that lactobacilli are the dominant microorganisms in growing fodder and play an essential role in silage fermentation. Fermentation in silage makes it possible to use silage fodder for a long time, without changing the nutritional value of the fodder. In Iran, silage is usually prepared with chopped corn plants (including stalks, cobs and leaves), but in countries where alfalfa production is high and drying it is difficult, alfalfa, barley, sorghum and clover silage is also prepared. to be

An overview of the characteristics of corn silage as the king of silage:

Today, corn silage is widely used all over the world and is considered as the basis of nutrition in many regions. The characteristics of corn silage have made it the best type of silage, so it is called the king of silage. The most important types of cereals that are used as animal fodder are corn, corn on the cob, sorghum, barley and rye wheat. Most of them are usually used green and less often as dry grass. Among fodder plants, corn has a special importance both in terms of the amount of the product and in terms of its nutritional value. Its seeds are used for human and animal feed and its green fodder is also silated, it is one of the best livestock foods. In places where corn grows well and is sufficiently irrigated, it is very suitable for silage, and if corn is harvested at the right stage and silated with great care, it will be one of the best and cheapest livestock foods. Silated corn is eaten by all animals with great desire and appetite, and it is the best food for dairy cows, cattle and sheep in winter. Green corn grass is very rich in cardboard, and the dried parts, i.e. stigmas, pods, dried leaves and the lower part of the stem, are rich in vitamin D.

In the picture above, you can see the chopped fodder corn that spends the first week of the fermentation stage to produce lactic acid and reduce the pH value.

In the above table, the characteristics of fodder corn silage of 30 and 750 kilos are mentioned.

The above table shows the technical and laboratory analysis of the packaged fodder corn silage

In the above picture, you can see the fermentation process table of fodder corn silage.

Fermentation process:

Fresh or wilted fodder is stored in a silo for fermentation or souring, and this place should be protected as much as possible against air entry and gas exit. The act of fermentation or souring makes fodder stable and prevents it from spoiling.

Souring or natural fermentation of silage materials is done by the vital actions of microscopic organisms that enter the silage along with the fodder, the most important of which are lactic bacteria:

Lacto Bacilloss = bacillos aci lactici

B. Cucumeris Fermentative

Are. As a result of the activity of this group of bacteria, the pH of the environment decreases and the action of microscopic organisms inside the silo is either completely stopped or reduced to a large amount. The airless environment and low pH of the silo hinder the action of other microscopic organisms that cause Corruption of proteins and amino acids (butyric bacilli) B. Buttyric (molds and fungi, etc.) Therefore, in order to produce good and quality silage, in addition to the conditions related to the type of fodder, the following three conditions must be met.

1) Removing air from the silo:

The more air inside the silo is evacuated, the better the quality of the silage will be. In order for the air inside the silo to be discharged more and at the same time to make more complete use of the space inside the silo, after pouring the chopped fodder into the silo, it must be pressurized regularly, thus the bacilli producing lactic acid will be at a higher level of activity. will do

2) Preventing the entry of air and the exit of gas:

Oxygen in the air has an unfavorable effect on the quality of the silo, and if its amount is reduced to a minimum in the silo and its re-entry is prevented, plant respiration will gradually stop and indirectly the temperature of the silo remains at a suitable level, thus the production bacilli Lactic acid generator starts working in this suitable environment and prevents the activity of spoilage microorganisms.

3) lowering the pH of the silo environment as quickly as possible:

The low pH of the environment disrupts or reduces the action of alkali-loving microorganisms, which are often harmful.

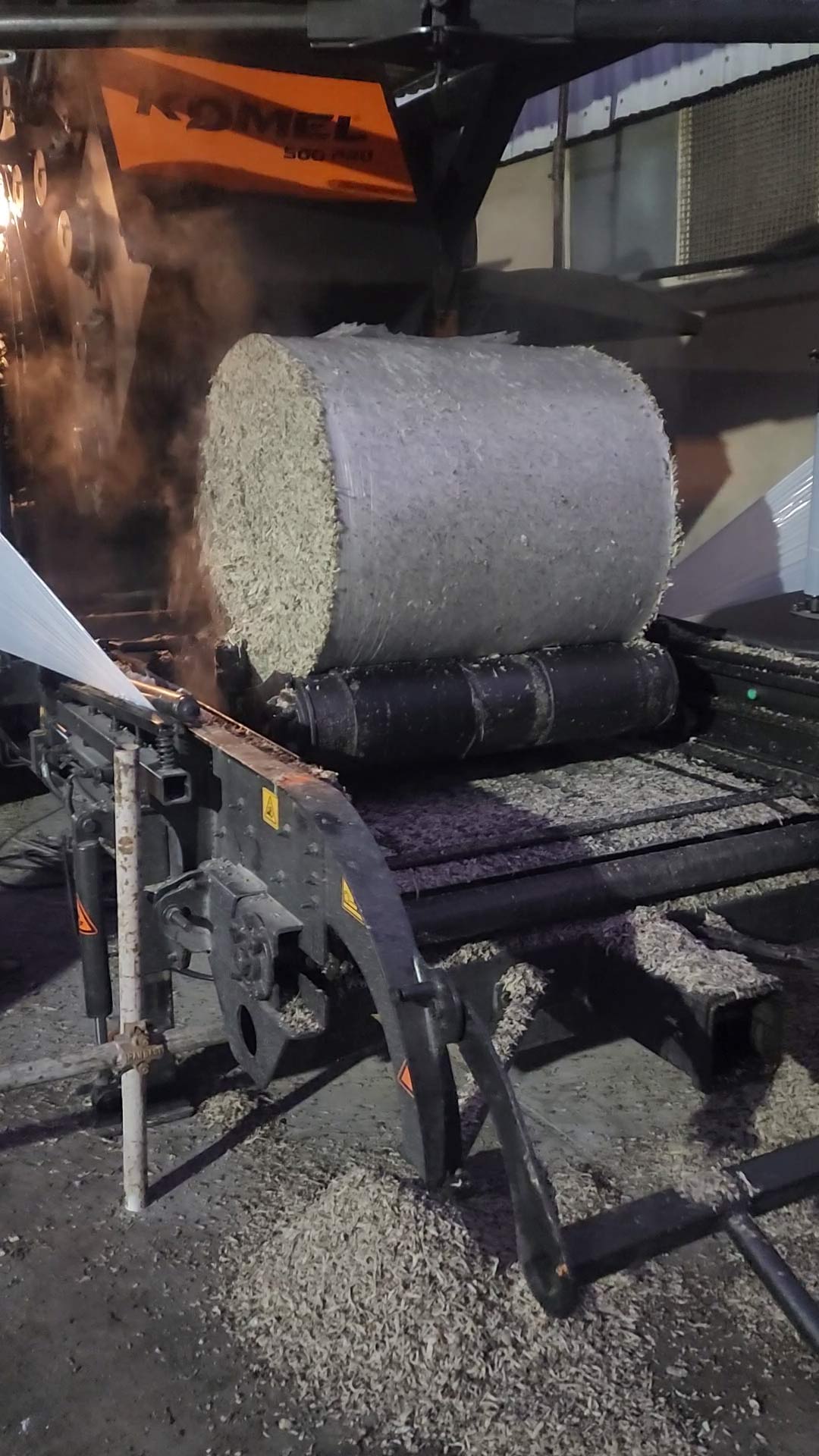

In the following, you can see the types of fodder packaging machines by clicking on the image below:

Fodder packing machine - silage of all types of fodder - special sale - cash and installments