Work with the baler on the farm

Javid Kesht Leyzeri Co.Ltd (Mardani Trading)

The packing operation should be done when the moisture content of the fodder is reduced to twenty percent. If the fodder is packed with high humidity, and due to the increase in the pressure of the density unit, it is possible to cut the shear pin or operate the friction clutch, the fodder will quickly mold after packaging.

It is better to pack the fodder in the early hours of the morning and the direction of the machine should preferably be in the direction of harvesting and sorting the fodder.

Steps to work with a baler in the field

1- Move the baler carefully to the farm and make sure not to hit the pick-up unit while crossing streams and ridges.

2- Enter the field with the baler in transport mode.

3- Place the baler in the working position inside the farm.

4- Move the baler with the tractor to the beginning of the fodder row in the same direction as the rower moved before and the fodder is drier than the other parts of the farm.

5- Place the baler on the row in a position where the pick-up covers the entire width of the row and the tractor is placed in the empty space between the two rows.

Working with a baler in the field

6- Set the receiver unit at the appropriate height.

7- Place the end plate of the condensation channel in a suitable position with a gentle downward slope.

Changing the position of the end plate of the condensation channel

8- Put the package length adjustment unit in standby mode.

9- Set the package count to zero.

10- Start the baler and increase the speed of the power transmission shaft to 540 to 1000 rpm (according to the machine model).

11-Slowly move the package on the fodder row.

12-Adjust the speed of the tractor according to the amount of fodder on the row so that the fodder enters the picker in the form of a tangled and uniform strip and at the same time does not accumulate too much in front of the guide forks. The speed of 5-9 km per hour is recommended for working with the package. But it is better for you to move at a speed of 5 km per hour.

13- Do not change the engine speed to improve the shape and size of the packages.

14-Continue packing until several packages are removed.

15- Stop the baler and check the removed packages in terms of the length and density of the package and the shape of the knot. Hold the two strands of thread with your hand and lift the package and check that the package does not fall apart and also that the threads do not tear after leaving the package from the compression chamber (channel).

Checking and controlling the length, density and knot of fodder packages packed with balers

16- If necessary, adjust the package length to the desired size by adjusting the package length unit.

17- If the package density is not suitable, adjust it to the appropriate level by turning the levers.

18- Restart the bailer and continue to create some more packages.

19- Check the produced packages again and continue making the necessary changes until you reach a suitable package.

20- After making sure that the package is suitable in every respect, continue packing the fodder row until the end of the field.

Fodder packing with baler machine

21- At the end of the row, disable the power transmission shaft by cutting off the power.

22- With the help of a ratchet and a rope, place the lifter in the upper position.

23- Place the tractor and baler at the beginning of the next row and do the packing operation.

24- After finishing the packing, empty the fodder in the car, collect the threads and move the car to its parking place in transport mode.

25-Perform 10-hour services on the baler.

Before starting the fodder packing operation with the baler machine, pay attention to the following points:

1- Carefully read the safety items mentioned in the manual of the device and remember the signs on the device.

2- Do not use the device as a vehicle.

3- When working, the guards must be installed in place.

4- To avoid accidents, do not use normal clothes while working. Also, to prevent hearing loss that may occur due to the continuous sounds of the baler machine, use a safety earpiece.

5- Avoid touching the knotting unit while the machine is working.

6- Avoid touching the threads and the outlet channel of the material, as well as pulling the material from the inlet opening while the machine is working.

7- The speed of the tractor when pulling and moving the machine should not be more than 25 km/h.

8- In case of crossing the roads that are used by other vehicles, be sure to use the appropriate lights and warning devices, and make sure that the color of the vehicle is healthy and clean.

9- When visiting the power transmission axles, if the car is on, stand at a safe distance and perform the inspection.

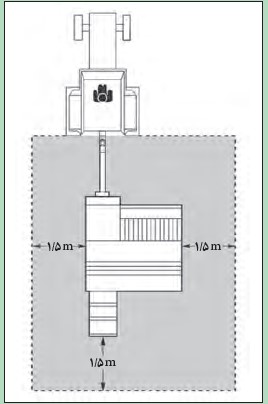

A safe distance from the working baler

Click on the link below to see the pictures of the Biler products:

Sale of balers (CLASS, FAMAROL, STAR, JOHN DEERE, GALLIGNANI)