Adjusting the baler device (elevator height, weight and length of fodder packaging)

Javid Kesht Leyzeri Co.Ltd (Mardani Trading)

Baler must be properly adjusted to create packages with uniform size and compression.

The settings made by the machine user are:

Adjusting the height of the receiver from the ground:

This height should be adjusted so that as much as possible no fodder remains on the ground. Fingers should usually go down so that their tips are between 20 and 30 mm from the ground, while slightly penetrating into the stubble or unharvested fodder. Contact of the fingertips with the ground can cause them to be eroded or bent, as well as the return of the finger due to impact causes the leaves to be crushed and the soil to be mixed with fodder.

Adjusting the height of the carrier from the ground

Adjusting the height of the carrier from the ground

Adjusting the height of the carrier is done in several ways, which include:

(a) Using a ratchet and a tow wire

Follow the steps below to set.

1 Pull the rope attached to the ratchet until the pulley is free and the fingers are close to the ground.

2 Pull the rope slowly to collect the cable reel and lift the lifter from the ground.

3 If the height of the fingers is low, pull the rope as often as necessary to adjust the height according to the ground conditions.

Adjusting the height of the lifter from the ground using a ratchet and a tow wire

b) With the help of height adjustment lever and adjustment pin

Do the following for this setting.

1- With one hand, lift the lifter to the required height from the ground.

2- With the other hand, move the adjustment lever and place its pin in one of the opposite holes.

3- To move the package and when the packaging work is not done, bring the adjustment lever fully forward, and in this case, pull the lifter completely upwards and put the pin of the lever in the corresponding hole.

Adjusting the height of the lifter from the ground level with the help of the height adjustment lever and adjustment pin

c) Using a hydraulic jack

In a group of balers, a hydraulic jack is used to adjust the height, and the raising and lowering of the lifter is controlled with a hydraulic valve that is available to the driver.

Adjusting the height of the lifter from the ground using a hydraulic jack

In order to prevent damage to the lifter and the fingers, a support wheel is installed next to the lifter in uneven, low and high terrains, which can be adjusted according to the height of the lifter. To adjust it, open the screw of the wheel base that is closed on the outer tray, and after adjusting the height of the wheel lifter, drop it to the ground, then tighten the screw in the place of one of the holes.

Retaining wheel

Adjusting the compression (weight) of the fodder package:

The amount of fodder pack compression is adjusted by the pack pressure adjustment screws located at the end of the compression chamber.

By tightening the adjustment screws, the upper and lower pusher poles are closer together and the movement of the fodder in the packing chamber becomes more difficult, thus the weight of the package increases and the fodder becomes more compressed.

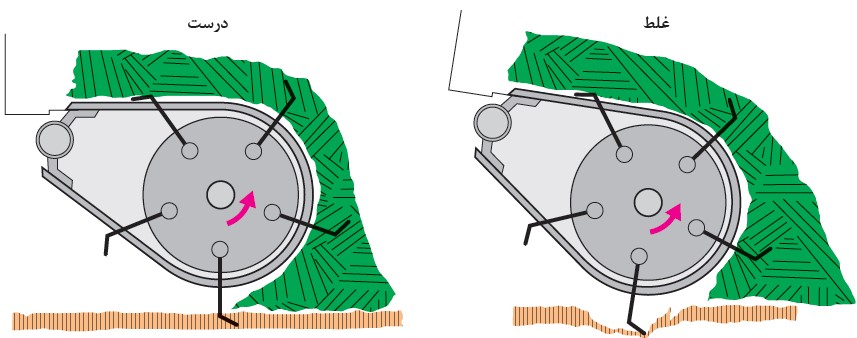

Pressing bars and its adjustment in the baler

Both adjustment screws must be adjusted to the correct position, otherwise curved packages will result.

Sometimes, due to the very lightness of the strips or the drying and puffing of the material at the farm level, the pressure adjustment screws may not be responsive and cannot create heavy packages, in such a case, installing side plates with conical projections in two The head of the packing chamber can be effective. The effect of these screens is greater when they are installed at the end of the packaging chamber, close to the exit opening.

Setting the package length:

In all baler machines, a star wheel is used to measure the length of the package, but despite this type of length adjustment mechanism in them, it may be different. In a group of balers, a sector gear is used to adjust the length. In this baler, in order to increase the length of the package, it is enough to engage more teeth of the sector gear, which results in a longer time to be released and fall down and knotting is done. To reduce the length of the package, a smaller number of gears of the sector gear should be engaged.

Adjusting the length of the fodder package in the baler machine

In some balers, length adjustment is done by moving the obstacle that slides on the release arm of the star wheel. In these balers, the star wheel rotates the predetermined number of revolutions, the release arm pulls the star wheel forward, and the release arm releases the clutch of the knotting machine.

Counting the number of packages:

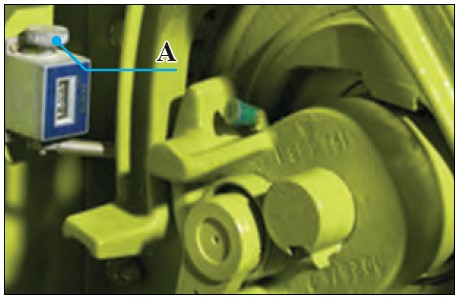

To count the number of packages leaving the output channel, a counter is installed next to the two connecting branches, which adds a number to the counter with each movement of the two connecting branches, which results in the formation of a package.

By turning button A in the figure in the opposite direction of the movement of the dial, its four digits will be zero. At the same time as zeroing, the special sound of internal gear locking (exact zero) is also heard.

Counting the number of packages in the baler machine

Click on the link below to see the pictures of the Biler products:

Sale of balers (CLASS, FAMAROL, STAR, JOHN DEERE, GALLIGNANI)