Getting to know the baler, fodder stringing unit, chassis, body and wheels and power transmission un

Javid Kesht Leyzeri Co.Ltd (Mardani Trading)

In the continuation of getting to know the baler machine, we will get to know the fodder threading unit, chassis, body and wheels and power transmission unit.

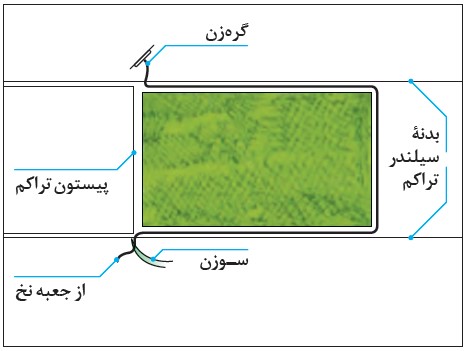

Fodder threading unit

The threading unit consists of two needles, two knotters and a star wheel key (wheel measuring the length of the package) which closes it with two rows of thread at the same time as the package is completed.

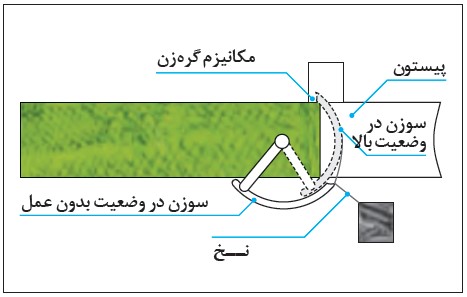

The threading unit works in such a way that gradually as the package is formed, the thread, one end of which passes through the knotter and the other end passes through the hole of the needle, surrounds the three sides of the package (top, back and bottom).

How the fodder threading unit works in the baler

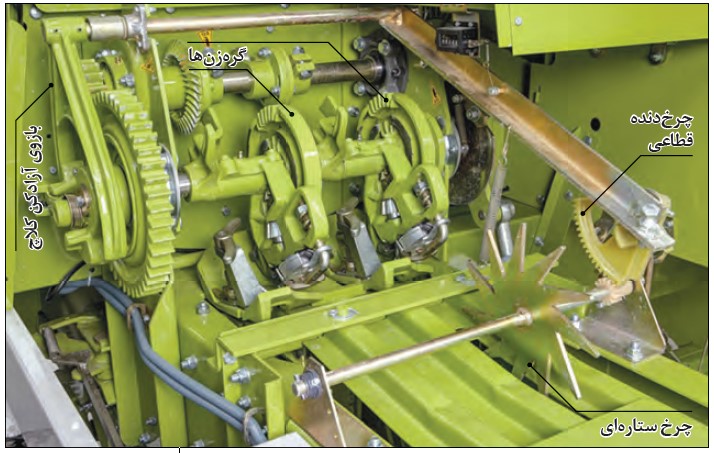

During the formation of the pack, while the pack moves backwards inside the compaction chamber, the blades of the star wheel penetrate inside the forage pack and the star wheel rotates with the displacement of the pack.

Star wheel and baler knotters

By moving a certain length from the package to the back of the machine, the star wheel releases the clutch of the knitting machine with the help of the release arm, and the needles and the knitting machine are used.

The activation of the knotting device is related to the movement of the piston, which means that the knotting cycle is performed in a short period of time when the piston goes back to the maximum and compresses the fodder completely.

Meanwhile, the needles (usually two needles) deliver the yarn through the slots inside the piston to the knitting machine and then return to their original position (at the bottom).

Knotting mechanism of baler threading unit

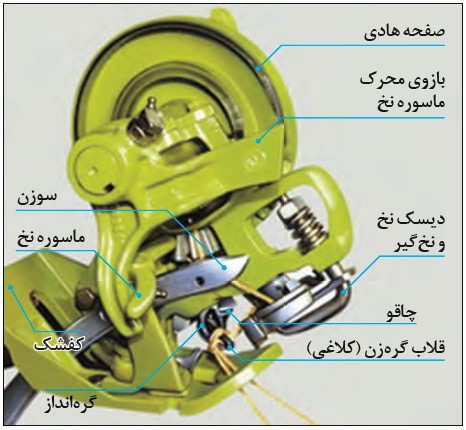

Usually, there are two knotting devices on top of the packaging chamber, which create two knots at the same time.

The main parts of each knitting machine are: yarn disk, thread catch, knitting hook, knife arm, knotter, knife.

Knotting components of baler machine

The task of the thread disk and the thread holder is to hold the thread tightly. The tying hook forms the knot and the knotter separates the knot from the tying hook and throws it out. The knife cuts the thread near the knot. All steps of this process are repeated every time a package passes through the packaging chamber. Finally, the package passes over the rear chute of the packaging compartment and falls on the ground or is loaded.

Leaving the package on the ground in the baler

Baler equipped with throw package

Chassis, body and wheels

The chassis is the main part of the fodder packing machine and includes a steel frame that is placed on two wheels and all the parts of the machine are installed on it.

Power transmission unit

The required power of the fodder pack is provided by the power transmission axis and the material of the pack. A gardan axle transfers the required power from the tractor's power transmission axis and through the safety clutch to the package, which has a flywheel in its path for a power balance.

Flywheel and safety clutch

Cutting pin from the rear view of the anchor wheel

This power is transferred from the flywheel to the gearbox by a shear pin and from there it is divided into three separate paths, which are:

1- Route of the threading and guiding unit: the power is transmitted to the threading unit by the key guard and at the same time it is transmitted to the guiding unit and the forks or the spiral cylinder of the guiding through the axis and the bevel gear and chain wheel.

2- The path of the pick-up unit: it is transferred to the chain wheel connected to the guard and then to the main axis of the fingers through the safety clutch.

3- The path of the compression unit: the power is transferred to the compression piston by the crankshaft and the piston handle.

The path of power transmission in the baler

Click on the link below to see the pictures of the Biler products:

Sale of balers (CLASS, FAMAROL, STAR, JOHN DEERE, GALLIGNANI)