Baler device - the second part, units for removing, directing and compacting fodder

JAVID KESHT LEYZERI COMPANY

The baler machine consists of the following main units: pick-up unit-fodder guiding unit (feeding)-fodder compression unit-fodder threading unit-chassis, body and wheels-power transmission unit

In this part of the training, the first three parts are presented, and the rest of the parts of the baler device are taught in the next part.

1-Receiving unit

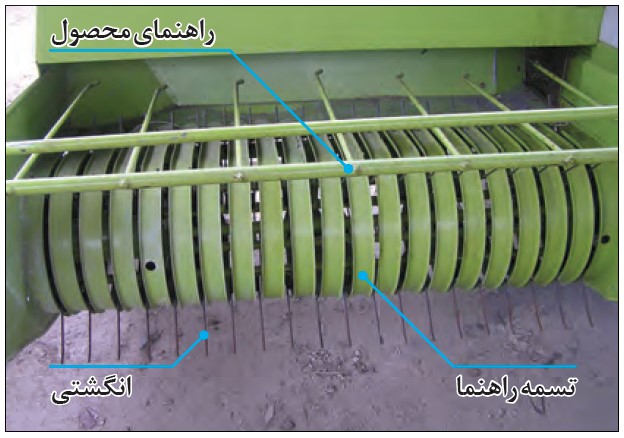

The pick-up unit picks up the banded fodder from the ground, lifts it up and delivers it to the guiding platform. The lifting unit is a cylinder consisting of four rows of spring-loaded fingers, these fingers slowly lift the forage strip during the rotational movement and take it to the guiding unit through the guide belts.

Baler conveyor unit

Components of the baler conveyor unit

2- Fodder guidance unit (feeding)

After passing under the product guide, the fodder reaches the part of the feeding platform and from there it is directed to the compaction chamber by means of forks or spiral cylinder.

The spiral cylinder of the fodder guiding unit of the baler machine

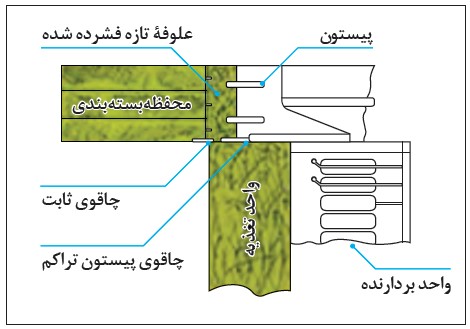

3- Fodder density unit

The compression unit consists of a piston and a packing chamber. The strips of fodder collected from the ground are brought into the compression chamber by the guides and compressed by the piston. Each time the piston moves to the beginning of its travel path, some forage enters the chamber, and the piston moves backwards, pressing some forage onto the previous forage, depending on the duration of the formation, slowly by each stroke of the piston to the rear. The container moves. Directing the fodder into the compression chamber and pressing it by the piston continues until the package is formed. Package compression changes by changing the pressure of the spring of the upper and lower pusher poles of the packaging chamber.

Fodder density unit

Click on the link below to see the pictures of the Biler products:

Sale of balers (CLASS, FAMAROL, STAR, JOHN DEERE, GALLIGNANI)