A GUIDE TO CHISELS And

JAVID KESHT LEYZERI COMPANY

A GUIDE TO CHISELS

The farm tools and equipment you use on your farm can have a significant impact on the success of your farm. Chisels, in particular, serve many important purposes when it comes to farming, and understanding what those purposes are can help you make more informed decisions when you’re shopping for farm tools and equipment for your operations. This week’s Richmond Brothers Equipment blog post provides a breakdown of chisels.

Richmond Brothers Equipment offers a wide range of high-quality tools that can lower your cost per acre, including chisels, ripper points, shovels, and much more. We’ve spent decades researching and innovating the highest quality, most reliable solutions that are designed to help increase efficiency on your farm while lowering your cost per acre. Read this week’s Richmond Brothers Equipment blog post to learn more about chisels, and reach out to our team of farm tool experts in Bay Port to get your chisels today!

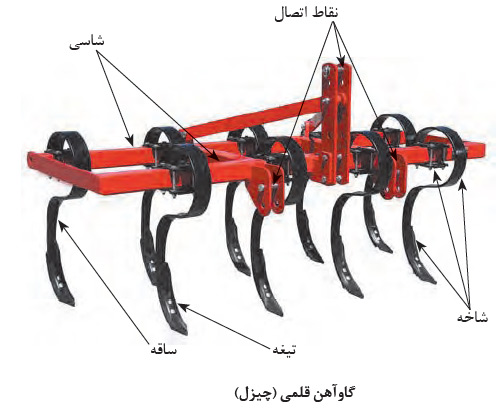

WHAT IS A CHISEL?

A chisel, or chisel plow, is a popular farming tool used for deep tillage. Its main purpose is to loosen and aerate your soil while leaving crop residue at the surface of the soil. Chisel plows work to reduce compaction. It’s important to know that, unlike many other tillage tools, chisels do not turn or invert the soil. Therefore, a chisel is a great tool for no-till or low-till farming, as it works to prevent erosion and helps keep organic matter on the surface of the soil throughout the year. Due to these factors, chisels are typically considered to be a more sustainable type of tillage tool than many others.

HOW DOES A CHISEL PLOW WORK?

Chiseling is typically performed in the fall and is then followed by secondary tillage come spring. Chisels are usually set to 8 to 12” deep, with the maximum depth at 18”. Chisel plows work to produce a rough surface and leave approximately 50 to 70% of the existing corn or grain residue on the surface of the soil. Each of the individual shanks are typically set from 9 to 12” inches apart.

BENEFITS OF A CHISEL PLOW

Chisel plows offer many different benefits, which can be found below.

- Loosening and aerating the soil

- Reducing the effects of compaction

- Loosening of the hardpan, which is a hardened, impervious layer of soil that impairs drainage and crop growth

- Reducing erosion for your soil, saving you money and offering sustainability

- Preventing any type of soil crust formation

- Severing weed roots below the surface, reducing growth of unwanted plants

Subsoiler

A subsoiler or flat lifter is a tractor-mounted farm implement used for deep tillage, loosening and breaking up soil at depths below the levels worked by moldboard ploughs, disc harrows, or rototillers. Most such tools will break up and turn over surface soil to a depth of 15–20 cm (5.9–7.9 in), whereas a subsoiler will break up and loosen soil to twice those depths.

The subsoiler is a tillage tool which will improve growth in all crops where soil compaction is a problem. In agriculture angled wings are used to lift and shatter the hardpan that builds up due to compaction. The design provides deep tillage, loosening soil deeper than a tiller or plough is capable of reaching. Agricultural subsoilers, according to the Unverferth Company, can disrupt hardpan ground down to 60 cm (24 in) depths.

The subsoiler consists of three or more heavy vertical shanks (standards) mounted on a toolbar or frame with shear bolts. They can be operated at depths of 45–75 cm (18–30 in) or more. A ripper normally runs 35–45 cm (14–18 in) deep. Shanks are curved and have replaceable tips. Each shank is fitted with a replaceable point or foot, similar to a chisel plough, to break through the impervious layer, shattering the sub-soil to a depth of 45–75 cm (18–30 in). Subsoiling is a slow operation and requires high power input: 60 to 100 hp to pull a single subsoil point through a hard soil. Typically, a subsoiler mounted on a compact utility tractor will reach depths of about 30 cm (12 in) and have only one thin blade with a sharpened tip. The shanks should be inclined to the vertical at an angle greater than 25-30 degrees, preferably 45 degrees, and it is advisable that the height be adjustable. The points of the shanks are normally about 30 cm (12 in) wide and should be easy to replace. The condition of the points is very important: often the subsoiler fails to give good results due to the condition of its points. Points can be fitted with horizontal wings, about 30 cm (12 in) wide, which considerably increases the width of soil below ploughing depth loosened by the subsoiler. These plows are sometimes equipped with a torpedo-shaped attachment for making subsurface drainage channels. The subsoilers are raised and lowered hydraulically. Some models feature power-take-off (PTO)-driven vibrating devices. The typical spacing is 76–100 cm (30–39 in) between shanks. Shanks should be able to reach 2.5–5 cm (0.98–1.97 in) below the deepest compacted layer. Shank spacing and height should be adjustable in the field. Towed subsoilers should have gauge wheels to control the shank's depth.

Shanks usually are from 2–4 cm (0.79–1.57 in) thick. Thinner shanks are suited for agricultural use. Thicker shanks hold up better in rocky conditions, but require larger, more powerful equipment to pull them and disturb the surface more.

Various manufacturers' brochures claim[citation needed] that crops perform well during hot and dry seasons because roots penetrate soil layers deeper to reach moisture and nutrients. Brochures further claim that in wet conditions, the water passes more easily through the shattered areas, reducing the possibility of crops drowning.

Agricultural subsoiler implements will have multiple deeper-reaching blades; each blade is called a scarifier or shank. Purdue University's Department of Agriculture indicates that common subsoilers for agricultural use are available with three, five or seven shanks. Subsoilers can be up to 15 feet (4.6 m) wide; some models are towed behind tractors while others are mounted to the three-point hitch.

One type of subsoiler has a torpedo-shaped tip and is called a mole plough because the tip describes a path much like the burrow that a mole creates. Mole ploughs are used to create tile drainage, with or without tiles or tile line added. A form of this implement (with a single blade), a pipe-and-cable-laying plough, is used to lay buried cables or pipes, without the need to dig a deep trench and re-fill it.