Fixing minor defects and maintaining the chopper machine during the working season and idle days

JAVID KESHT LEYZERI COMPANY

The chopper user must have the ability to fix some minor faults of the machine. The most important of these defects is the slowing down of the blades of the cutting cylinder and the lack of adjustment of the belts and chains of the machine.

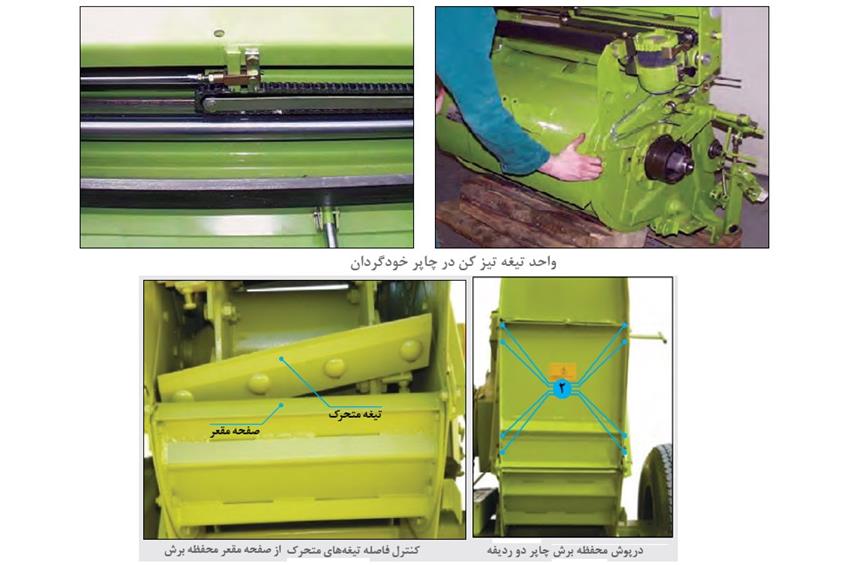

Sharpening the moving blades of the cutting cylinder:

In order for the harvested fodder to be chopped evenly, the moving blades and the fixed blade must be sharp and adjusted to each other. For this reason, equipment for sharpening the blade has been placed on these machines. The sharpening blade unit consists of an emery stone and a rail on which transverse movement takes place.

The sharpening blade stone has two types of movement in width and depth. In transverse movement, the stone sharpens the entire length of the blade and makes the blades sharpen uniformly in an equal radius, and in vertical movement, the depth of sharpening the blades is adjusted. to be

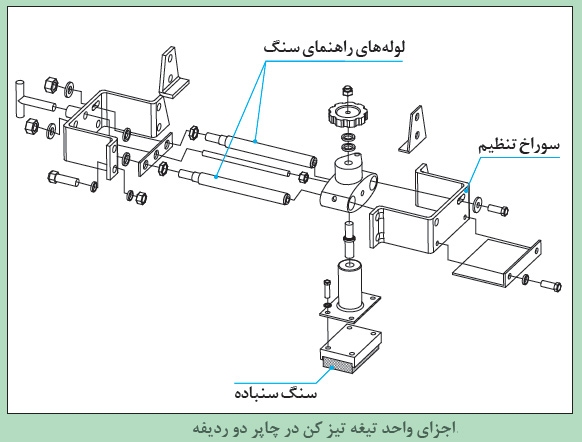

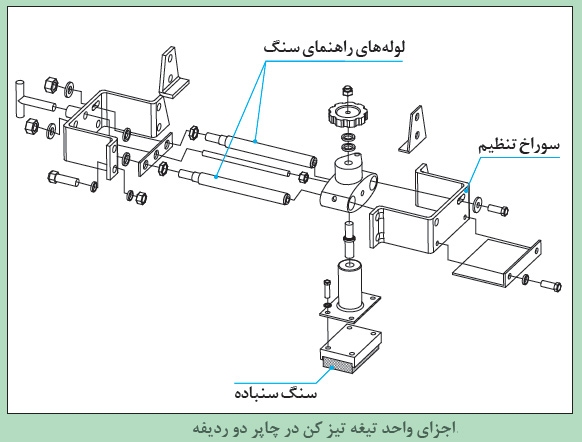

In two-row choppers, horizontal and depth movements are controlled manually.

The connection point of one of the pipes on which the sanding stone moves transversely is adjustable.

In the self-driving chopper, the horizontal and depth movements of the stone are made by turning on the starter control key, and this operation continues as long as the user feels the need.

In addition, in self-propelled choppers, the control of the vertical movement of the stone can be done manually, especially for the first sharpening. To move the stone manually, the release button must be pulled.

Note: Before sharpening the blades, we must make sure that the distance of all moving blades from the fixed blade is the same.

Sharpening the moving blades of the cutting cylinder in the two-row chopper

1- Open the protective frame of the sharpening stone.

2- Turn the handle of the blade stone (pictured below) slightly counter-clockwise until the setting stone flake is released.

3- By rotating the stone blade (figure below) counterclockwise, lower the stone to a distance of 2 mm between the moving blades.

4- Turn the handle of the stone clockwise until the setting plate is tight.

5- Run the blades at half speed.

6-Turn the regulator counterclockwise to gradually lower the stone.

7- When the stone is completely close to the blades, move it back and forth by the handle of the stone to sharpen the blades.

Always grind the entire length of the blades.

8- After sharpening the blades, by turning the regulator clockwise, move the stone slightly up and then to the left side.

9- Move the adjustable tube (picture below) so that the sanding stone cannot move while the chopper is working.

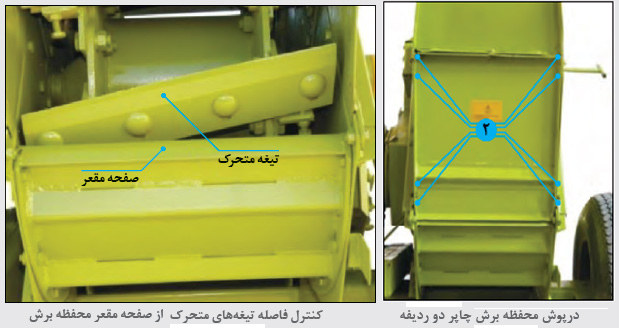

10- When you have sharpened the moving blades several times, their distance with the fixed blade should be adjusted. The distance between the moving and fixed blades should never be more than 0.5 mm, otherwise too much force is required for crushing.

11- Loosen the screws of the cover of the cutting chamber (picture number 2 below).

12- Check the distance of the blades from the concave surface of the cutting chamber. This distance should be from 0.5 mm to 4 mm. (Figure above)

Note: If the distance between the blades and the bottom plate of the cutting chamber is increased, the throw will not be performed well. Improper launch indicates a large distance between the blades and the bottom plate of the chamber, and their distance must be adjusted.

13- After setting, close the cover screws of the chamber.

Note: If the concave plate of the cutting chamber has been adjusted several times and there is no place for further adjustment, proceed as follows:

1- As much as possible, close the concave plate to the outside and direct the fixed blade to the back. Also adjust the movable blades with the adjustment screws and tighten their nuts.

2- Bring the fixed blade as close as possible to the moving blades and change the location of the concave plate until the distance is set correctly.

3- If the movable blades need to be sharpened again, readjust the fixed blade with them until the distance between the blades and the concave plate is reduced so that the amount of throw is increased.

Safety: When sharpening the blades, make sure that the stone flake is secured by the handle.

Maintenance of the chopper machine (fodder corn harvester) during the idle season

Steps to do the work:

1- Run the car for a while and then remove and replace the oil of each gearbox.

2- Clean the fodder and extra materials from the car and clean the car completely.

3-Grease all grease fittings.

4-Remove the lifting chains and clean and lubricate the wheels of the chains and the related places completely, and then install the chains.

5- Clean and lubricate the blade and related parts.

6- Clean and lubricate all the movable and fixed blades of the fodder cutter.

7- Open the car wheels and replace them with wooden or cement blocks and never deflate the wheels.

8- Replace worn out parts.

9-Repair and then paint the parts of the car that are rusted or their paint has spilled.