How to perform fodder corn harvest with a chopper

JAVID KESHT LEYZERI COMPANY

The operation of harvesting silable fodder with a chopper should be done optimally and planned so that while saving money and time, the work efficiency or farm capacity of the machine can be raised as much as possible. We achieve this goal when we act according to the predetermined plan and plan.

The path of the machine: should be chosen so that the tractor moves in the direction of the atmosphere and the stacks so that the cultivated rows are in the direction of movement.

In self-driving cars, for the first route, the discharge pipe is placed in the rear direction and the transporter moves behind the car. But in tractor machines, due to the fact that the machine and the tractor do not move in the same direction and the chopper is placed on the right side of the tractor, the path of movement must be chosen in such a way as to prevent the unharvested stems from being crushed under the wheels of the tractor. For this purpose, if possible, the first path should be taken from the side of the field, and if there is no empty path around or in the middle of the field, it is better to manually harvest the width of the tractor along the length of the field and then enter the field. Otherwise, without a doubt, a part of the product will be crushed under the wheels of the tractor and will be out of reach.

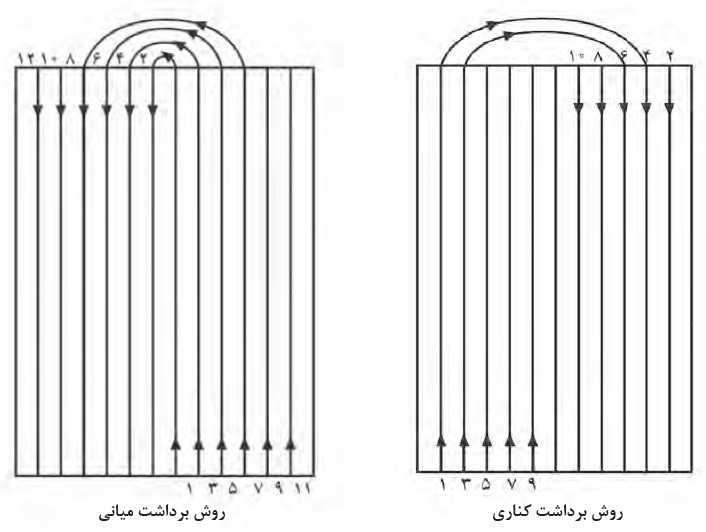

To determine the next paths, like plowing with a one-way plow, the middle or side method can be used.

Choosing the right time in terms of soil moisture:

One of the important factors is harvesting fodder with a chopper. Because high humidity may cause the wheels to sink into the soil and stop the machine, or the wheels to sink may cause the force required to pull the machine and the tank to increase too much, and ultimately, reduce the working efficiency of the machine.

Choosing the right transport vehicle:

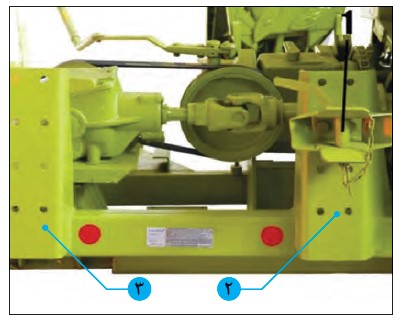

It is one of the important factors in changing the work efficiency of the machine. It is better to consider a tractor for harvesting operations and transfer the harvested fodder with another tractor or truck. However, all fodder corn harvesting machines have a rear tow bar to which the rolling pin can be directly connected. In two-row cars, this piece can normally be attached to the right side of the chassis (number 3 in the figure). In more difficult conditions, for example, when the car is working on a sloping surface or soft ground, it can be closed on the left side (number 2 in the picture). When moving on the road, the tow truck must be turned to the right.

In the situation where the two-wheeled scooter is connected to the car, since some of the scooter's weight is transferred to the car, the axle of the car wheel should be connected to the rear holes of the chassis.

Checking the quality of the product passing through the discharge pipe: it can be seen by being a few meters away from the machine during work, and you should always pay attention to this issue during the harvest season. During loading, the crushed product should come out of the pipe in the form of a thin sheet and at the end of its main passage, it should be diverted and spread into the transporter.

If the harvesting operation is accompanied by wind, start harvesting from the side so that the product coming out of the discharge tube does not fall on the machine due to the wind.

Adhering to the transverse distance between the transporter and the chopper: the transporter should be placed at a distance from the chopper such that the end of the discharge pipe is in the middle of the width of the machine room, and the discharge pipe should be placed in the middle of the transporter (longitudinally) while it is perpendicular to the direction of movement. .

Harvesting corn by chopper

1- Move the chopper to the corn field in transport mode.

2- Put the printer in working mode.

3- Lead the chopper from the left side into the field. In this case, the tractor will move on the edge of the field and the chopper will move on the right side of the tractor in the row of fodder.

4- Place the chopper so that it is along the fodder row.

5- Place the separating plate on the side of the machine at a height that completely pushes aside the stems lying on the row being harvested.

6- Start the chopper by pulling the starter lever.

7- With the help of hydraulic jack, put the nose at the right height.

8- With the help of the manual gas lever, adjust the tractor engine speed so that the power transmission axis rotates at 540 or 1000 per minute.

9- According to the height and width of the product, select the appropriate gear based on the required speed and engage the gear.

10-Slowly release the clutch and guide the chopper in the crop row so that the corns are in the path of the cutting blade and the guide chains.

11- Guide the chopper slowly along the rows. While working, avoid increasing and decreasing the forward speed, engine speed and gear change.

12- With the help of the lever, direct the discharge pipe in the right direction to the trailer or truck and when harvesting, constantly monitor the path and place of fall of the fodder inside the roller. Adjust the output direction of the drain pipe with the help of the relevant levers, so that different parts of the tank are filled uniformly.

13-Choose the forward speed according to the farm conditions.

14- During harvesting, check the length and adequacy of the cut pieces.

15- When necessary, raise and lower the nose of the machine to prevent the nose from hitting the ground while respecting the cutting height.

16-Continue harvesting to the end of the ground. At the end of the ground, make sure that the chopper is completely unloaded, and then reduce the engine speed with the hand throttle.

17- Push the start lever in until the shredder stops working.

18- Put the chopper in the next path according to the harvesting pattern and repeat the previous steps.

Attention: when turning around, go through an arc that avoids the collision of car parts with the tractor and the rear wheels of the tractor. In addition, when the tank is connected to the device, choose the right direction of the tank so that the track will pass through the selected paths.

19- At the beginning of each row, activate different parts of the car. Then approach the rows of crops so that when the cutting blades hit the bushes, the blade is working.

20- If a large amount of fodder enters the feeding area during harvesting, push the trigger lever inward and at this time, stop the chopper so that the excess product is removed from the chopper. Then continue harvesting by pulling the starter lever.

21 - Prevent the accumulation of fodder in the cutting blades of the machine. In such a situation, try to solve this problem by reducing the advance speed or stopping the machine and on the other hand by reversing the rotation direction of the feeding cylinders.

Note: In case of accumulation and clogging, open the valve on the chamber (inspection valve), remove the fodder from inside the machine and close the chamber again and continue harvesting.

safety

- When the device is not active, it is necessary to place the nose at a higher height than the ground to prevent it from hitting the ground.

- Be careful, before the tank of the truck is full, stop the harvesting operation, empty it or replace it.

- Consider increasing the height of the tank walls to such an extent that the weight and the tank when it is fully filled will not cause problems for the tractor.

- When the car is idling or inactive, put the gear box in neutral.

- Javid Kesht Laseri Company, men's agricultural machinery, importer of all kinds of German Jaguar CLASS chopper machines, German KEMPER head

Click on the following links to view product images:

Sales of German KEMPER heads

Types of choppers behind the TINAZ tractor in Turkey

German Jaguar CLASS chopper-with German KEMPER head