Adjusting the fodder corn harvesting machine: the third part of the unloading unit and the accelerat

JAVID KESHT LEYZERI COMPANY

emptying unit

The discharge unit includes the discharge pipe and the equipment related to moving the pipe. Because the product enters the transport machine directly after cutting, choosing the right discharge tube and controlling it in different directions is of particular importance.

A) Choosing the right pipe:

The drain pipe should be selected according to the height and length of the transporter.

If we use a long pipe in a truck with a short tank:

1- When the wind blows, there is a lot of product loss.

2- It is difficult to control the head of the pipe and as a result, the product is not guided well across the transport machine.

If we use a short pipe in a truck with a long tank:

1- There is a high risk of the pipe colliding with the truck when turning around.

2- If the transversal distance between the transport machine and the corn harvesting machine increases, the product loss will increase.

B) Drain pipe control:

The drain pipe has three types of movement:

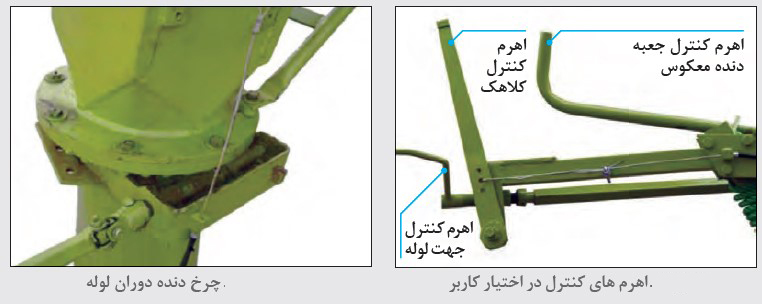

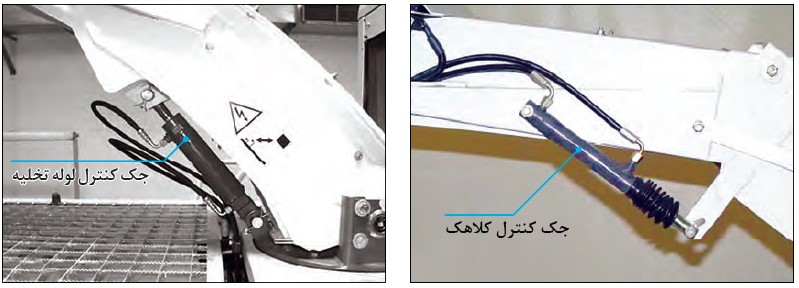

1-Rotary movement: the discharge tube from the throat part has a rotational movement, this rotation allows the driver to control the length of the output product.

2 vertical movement of the tube head cap: the cap moves vertically up and down. This movement allows the driver to control the lateral movement of the product from the exit.

3- Vertical movement of transportation: In the mode of transportation, the drain pipe should be placed towards the back of the car. In self-propelled choppers, the discharge pipe is placed in its own seat in the transport mode, but the two-row choppers do not have a pipe seat. In the picture below, you can see the seat of the drain pipe.

Pay attention: because the exhaust pipes are heavy and their torque is high on the throat, in the two-row chopper, due to the lack of a seat, we must move slowly during the transport to avoid shock and impact to the pipe. In self-propelled choppers, be sure to place the tube on the seat.

accelerator unit (launch)

In self-driving machines, before the crushed product enters the discharge pipe, it passes through a part called an accelerator to gain more speed and easily travel the discharge path. The accelerator is a rotating cylinder on which a number (usually 8) of blades with special teeth rotate at high speed and apply a large force to the chopped product.

The acceleration of the output product can be changed by moving the accelerator horizontally forward or backward. The more we bring the throwing cylinder to the rear of the machine, the faster the chopped product moves.

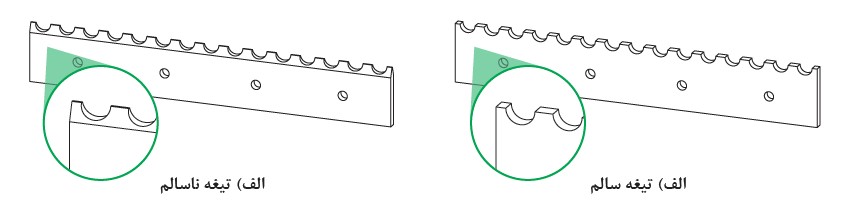

The blades installed on the accelerator are toothed, if the teeth are sharpened or lost due to corrosion or a part of the blade is broken, it must be replaced.

Adjusting the discharge pipe in the tractor's two-row chopper

1. Turn the drain pipe in different directions with the drain control lever.

2- Change the position of the cap using the control lever.

3- Place the drain pipe in the transport position.

Note: In self-driving cars, the tube and cap are controlled from inside the cabin and hydraulically.

Click on the following links to view product images:

Sales of German KEMPER heads

Types of choppers behind the TINAZ tractor in Turkey

German Jaguar CLASS chopper-with German KEMPER head