Methods to prevent fodder spoilage

javid keshtleyzeri Co.ltd

The moisture in the fodder is a suitable place for the growth of all kinds of fungi and microbes, and the presence of this moisture and as a result of the fungi and microbes leads to mold and spoilage of the fodder, which is caused by making the environment alkaline or acidic for the growth of microbes. It is possible to prevent the spoilage of wet fodder.

Creating an acidic environment:

To create an acidic environment, we can use edible acids, but the use of these materials is expensive. Therefore, the best way that can be suggested is to use beneficial microbes. These microbes exist around us, but only in environments where there is no air, they have the ability to overcome harmful microbes and fungi. For this, it is necessary to provide the right environment for their growth. Now the question is, what kind of environment should be suitable for the growth of useful microbes? An environment that is suitable for humidity, sugary substances and lacks air.

Forage moisture:

The suitable humidity for fodder is 65 to 70%. If the amount of moisture is more, it will cause problems due to excessive acidity. To reduce moisture, we add dry straw to the fodder, but moisture less than 55% will cause less acid production and the silage will spoil. To provide moisture by adding water, we increase the moisture to 65% (to estimate the moisture level, hold a handful of fodder in your hand and squeeze it tightly, if the water comes out, the moisture is more than 70%, and if your hand does not get wet, the moisture is less It is from 50%. The right humidity is when only your hand gets wet).

Sugary substances in fodder such as fodder corn, barley, sugar beet pomace, beet leaves, green artichoke naturally contain enough sugary substances (carbohydrates). But fodder such as clover, alfalfa, fresh tomato pomace, and citrus pomace have less sugar content, and enough sugar content should be added to it by adding molasses or barley flour.

For this, we add half a kilo of molasses or three hundred grams of flour for every ten kilos of dry fodder and mix it.

Air release from fodder:

To remove the air from the fodder, we press and compress it with the pressure of heavy objects such as a heavy roller with the pressure of the wheel of a tractor or other vehicles, and then we make it impermeable to air by using nylon. If you have traditional (small) silage at your disposal, prevent air from entering by pulling a wide nylon (6 meters wide) and then pouring soil on it, otherwise, you should spread a wide nylon on the ground and after pouring the material on it cover it again with plastic and protect it from wind, rain and sunlight with heavy objects such as dirt or worn tires; Of course, you can do this in any environment that lacks air, such as a plastic barrel.

Note: Be careful to choose the place of the silage land in such a way that during the rains, water does not collect there and mice and other rodents cannot dig holes to cause air suffocation and spoilage of fodder.

Alkalizing the environment:

The second way is to alkalize the environment to prevent the growth of harmful microbes. Of course, it should be noted that acidification is a much better method and the fodder produced is tastier, but in cases where the sugar content in the fodder is low, we inevitably use this method. For this we have to use alkaline chemicals, these substances like caustic soda or ammonia are very dangerous and their use is not recommended. But the use of urea fertilizer is very appropriate due to the presence of urea and the release of ammonia inside the silage. For this, several points must be observed:

Suitable humidity:

The suitable humidity for this work is between 60 and 70%, as mentioned earlier, it can be adjusted and created with different methods.

Bleeding:

In this method, it is not necessary to press the fodder with heavy objects, and only the pressure of small manual rollers and the pressure of the worker's foot is sufficient.

Addition of urea to silage forage:

To add urea, 20 kilos of urea fertilizer should be added for each ton of dry matter of fodder.

How to store fodder in acid silage and how to use it:

Acidic silage can usually be used immediately after preparation, and it can be used gradually by removing a part of the nylon. But it should be noted that if the air reaches the fodder, the fodder will rot after 36 hours and the parts exposed to the air should be consumed quickly and with a depth of 15 cm daily.

Note: If not opened, the silage can be used for many months. However, in case of rainwater or drain water entering, the nylon being pierced by mice or animals and humans and opening on the silage quickly and within a few days, the parts exposed to the air become rotten and unusable. Fodder consumed in different livestock is different and (about 1-2% of the animal's body weight) is in the form of dry matter.

Allowed amount of consumption and method of consumption of alkaline silage: In this silage, fodder can be used after twenty days, and due to the pungent smell of ammonia, it must be aerated before use. At least 3 hours before consumption of fodder, it should be removed from the silage and placed in the open air, and by gradually consuming it, the animal will gradually get used to eating it. The amount of consumption of this type of silage for all types of livestock can be up to 1% of the animal's body weight in the form of dry matter.

Note: the duration of the animal habituation period to alkaline fodder is 10 days. During this time, the animal will get used to it gradually and if necessary by mixing the fodder with other foods.

Necessary recommendations for fodder consumption in different livestock:

cow:

The fodder prepared in acid (fermented) silage can easily provide up to 50% or half of the dry matter of the daily feed of dairy cows, and due to the low cost of preparing these fodder, the cost of milk production will be saved. Also, it is easily used for feeding 6-12 month old calves and dry cows and bulls. Alkaline or ammonia silage is only recommended for low-producing dairy cows that produce less than 18 kg of milk, and its use is not recommended for calves up to 6 months old; But its consumption is recommended for bulls. But it should be noted that during consumption, the fodder provided to livestock should be consumed together with grain such as barley or concentrate. In case of ammonia poisoning, the animal can be treated with vinegar (a mixture of half a liter of vinegar and half a liter of water).

Sheep and goats:

The use of fodder prepared in acid silage is safe for sheep and goats, and by using this fodder in the ration of fattening lambs, the cost of feeding them will be saved a lot. The consumption of fodder can be up to 40% of the dry matter consumed by the animal. Fodder prepared in alkaline (ammonia) silos can also be used for Sikh sheep and goats, but it is recommended only in the conditions that the animal's ration contains enough sugars (barley, wheat and concentrate) as well as enough water. This fodder can be consumed up to a maximum of one kilogram per day.

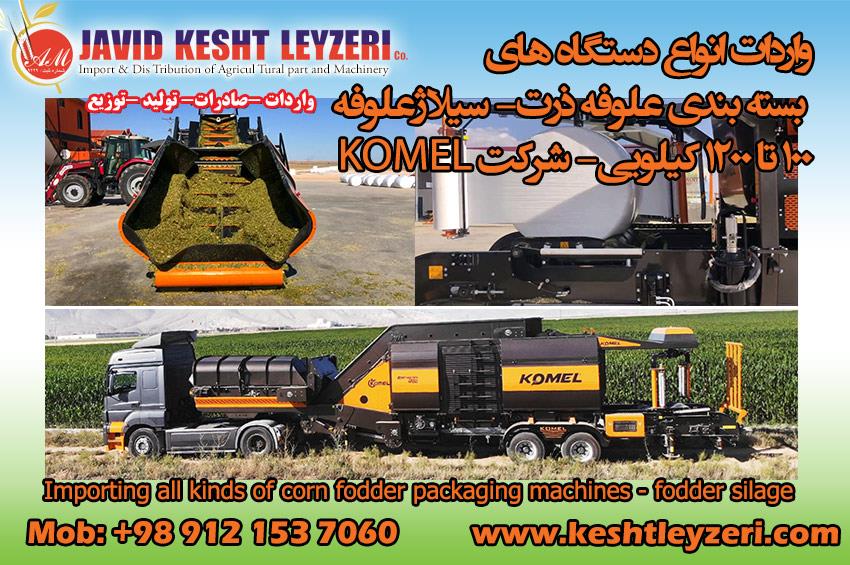

Certainly, by using silage and fodder packaging machines, the moisture level of fodder can be better controlled, which you can see by clicking on the image and the link below:

Fodder packing machine - silage of all types of fodder - special sale - cash and installments