Fodder corn harvesting machines

JAVID KESHT LEYZERI COMPANY

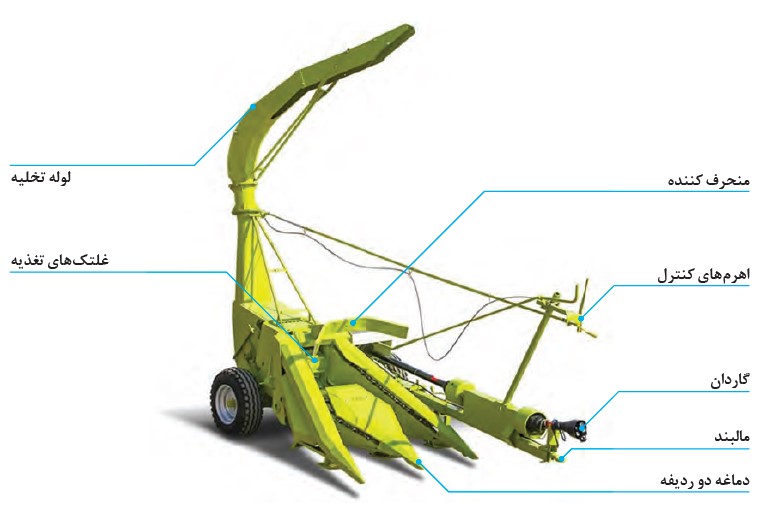

Generally, a forage maize harvester or chopper is used to crush fodder corn in the field and guide it into a trailer or truck. These machines are divided into self-driving and traction in terms of the required power supply. Self-driving cars are those that are equipped with a driving engine, while in the traction type, a power supply source such as a tractor is needed.

Autonomous chopper

Traction chopper behind the tractor

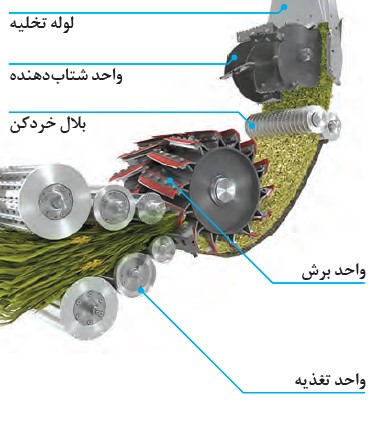

Both types of machines harvest the fodder stem from a few centimeters of the ground while moving, or lift the harvested fodder from the ground and guide it to the cutting unit.

The fodder is cut to the same size in the cutting unit, and with the created acceleration, they enter the transporter through the discharge tube.

Harvesting corn by self-propelled chopper

Therefore, despite the difference in the type of chassis, body and power supply, all fodder corn harvesting machines have several main units:

1-Harvesting and product guidance unit (head or nose): Harvesting of fodder is done in this part.

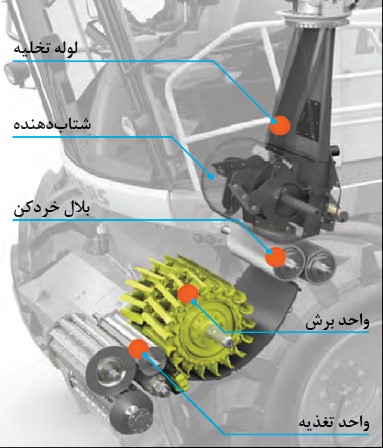

2-Feeding unit: The feeding unit consists of a number of rollers whose duty is to take the fodder from the nose and uniformly direct it to the cutting unit.

3- Cutting unit: crushing corn and guiding it to the emptying unit is done in this part

Note: In self-driving machines, the cutting unit also includes the shredder.

4- Discharge unit: The task of this part is to guide the crushed product to the transport machine.

Note: The emptying unit in self-driving cars also includes a switch.

5- Power transmission unit: This unit has the task of transferring power to other car units and includes several gearboxes, gearboxes, belts and chains and safety equipment.

You can see the feeding, cutting, cob shredder, accelerator and discharge units in the self-driving chopper in the pictures below.

The location of the units on the car

Movement of fodder in machine units

To see the pictures and videos of the products, you can refer to the following links: