Aeration of fuel system of agricultural tractor

javid keshtleyzeri Co.ltd

Refer to the manual for venting the fuel system of each engine.

Required equipment: work clothes, cleaning cloth, suitable wrench

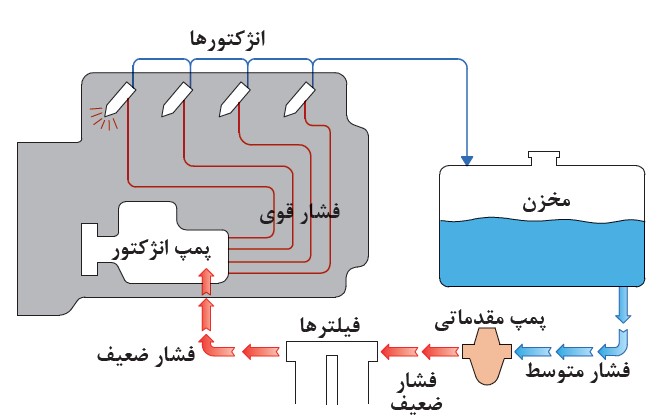

Fuel system ventilation path

1 Find the cause of air entering the fuel circuit and eliminate it.

2 Loosen the fuel strainer vent screw.

3 Move the primary pump lever up and down continuously (pumping) until the fuel without bubbles comes out from under the vent screw. Tighten the vent screw at the same time.

4 Loosen the ventilation screws on the injector pump.

5 Pump with the hand pump lever to remove airless fuel from the vent screws. At the same time, another person first tightens the lower screw and then the upper screw.

6 Loosen the neck nut of the fuel inlet pipe to the heater plug and ventilate it by pumping the hand pump.

7 Loosen all the throat nuts of the injector pipes in the cylinder heads.

8 Start until diesel comes out of the injector pipes. Then tighten the injector nuts.

9 Turn on the tractor by hitting the starter. If the engine is running erratically, repeat all the ventilation steps.

In some cases, the hand pump lever does not move. In such a situation, turn the crank one round in the direction of your movement.

Place a container under the parts that are ventilated to prevent diesel from splashing into the environment.

Aeration stages of the fuel supply system