Potato harvesting machines

Javid Kesht Leyzeri Co.Ltd (Mardani Trading)

Harvesting potato, which is a tuberous product, consists of three stages; Removing the tubers from the soil, digging and collecting the tubers. Potato harvesting machines may be automatic and perform all the above steps mechanized, but most potato harvesting machines (common types in Iran) are semi-automatic and are only capable of removing the tubers from the soil and removing the soil. give After digging, these machines leave potatoes on the ground in a row, and the operation of collecting potatoes from the row is done by a worker.

In general, the process of taking out potato tubers is a bag in all the tools and machines used in harvesting potatoes, and the difference between them is in the method of digging and collecting the tubers.

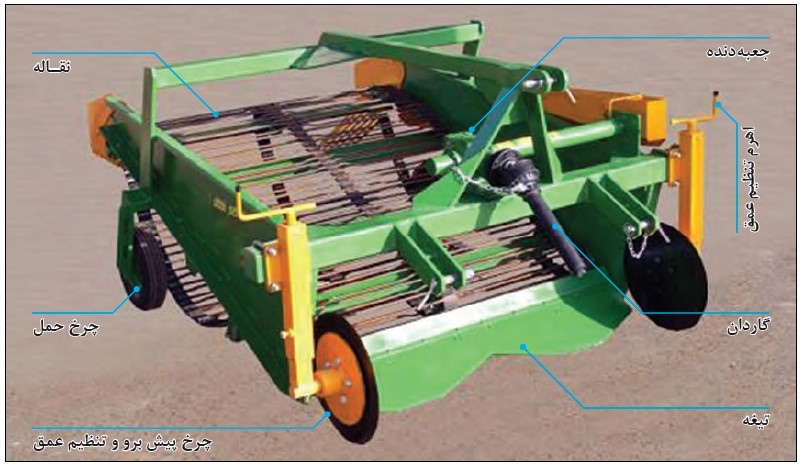

Potato elevator digger

The different components of this device are: blade, conveyor, gearbox, safety clutch, power transmission parts, adjustment wheels, depth, carrier wheels, shaker.

Conveyor potato

The conveyor potato machine cuts the soil and potato tubers from the lowest place by means of a blade, and guides them to the conveyor belt. With the movement of the conveyor and the vibrations that occur in it, most of the soil is separated from the potato from the distance of the conveyor, and the potato tubers fall on the ground from the end of the conveyor in the row furrow, which is finally collected by the worker from the field surface. They are brought.

This type of potato can be made in the form of a row or two rows, which may be single-row or double-row.

Types of potatoes with a two-row conveyor

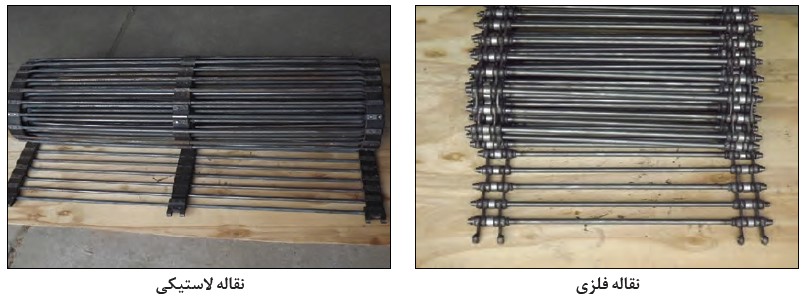

There are two types of conveyors: metal and rubber (European).

Types of potato conveyors

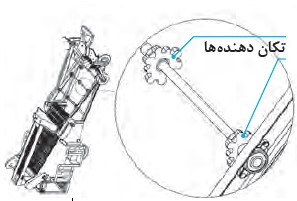

The necessary force for the movement of the conveyors is provided by the tractor's power axis, which reaches the conveyors after changing the rotation and direction in a gear box by a chain wheel. In the power transmission path of these machines, a plate safety clutch is placed, which cuts off the power transmission in case of overload. Conveyors are loosely tied to collect soil from the tubers on their way, in addition, a number of shakers have been placed in the way of conveyors to improve the process of soil collection.

conveyor shaker

At the end of some of these potato cans, a leveling roller is installed to facilitate the collection of the product. In addition, conveyor potato harvesters have the ability to install pre-pressure rollers in front of the machine to further crush lumps and increase harvest quality.

Flatten your roll

Pre-pressure roller

In fields where it is not possible to work with a tractor, you can also use a special potato tiller conveyor.

Conveyor potato for two-wheeled tractor

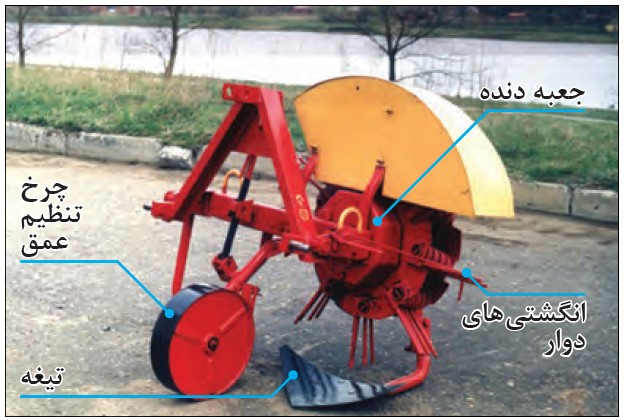

Potato spinner

The rotary corn potato is pulled by a tractor and its different parts are: chassis, blade, rotary fingers, depth adjustment wheel, gear box and side cutting disc.

Turn potatoes

The rotary potato is usually made in two ways: pulling and riding. The necessary force for the rotation of the rotary fingers is provided by the ground wheel in the traction type and by the power transmission axis of the tractor in the riding type. The basis of the work of this type of potato digger is based on the rotation of the rotary fingers, which during the rotation throws the stack of soil along with the potato tubers that have been pulled from the ground by a blade, the soil and tubers Thrown, it hits the wire net and some of its soil comes out of the net and the tubers fall on the surface of the soil, then they are collected by the worker.

Rotary potato in operation

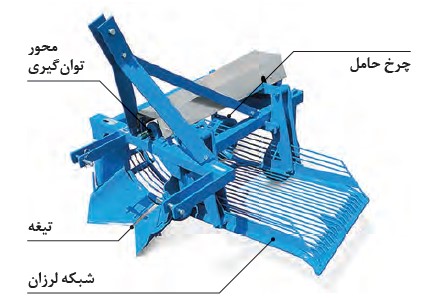

Potato shaker digger

The different parts of the vibrating potato planter are: chassis, blade, grid, gear box and carrier wheels. The working method of this type of potato planter is that the triangular blade has a gutter shape with a bottom and side cut at the appropriate depth of the pile soil along with Cuts the tubers. Due to the progress of the machine, the cut soil is transferred on the vibrating grid. Most of the soil is removed from the distance between the bars of the vibrating network. Also, the soil clods are crushed and potato tubers fall on the soil from the end of the vibrating net, which is collected by the worker. The power required to move the vibrating net is supplied from the power axis of the tractor. A crank mechanism converts the rotary motion of the axis into reciprocating motion of the web.

Shivering potatoes

Potato combine

This device is an advanced type of conveyorized potato machine and its use is recommended in large fields.

The working method of this device is that the pile of soil including potato tubers is removed by the blade and is guided to the conveyor part.

Potato harvester

The piled soil passes over the conveyor during the progress, with the created shocks, a part of the soil is separated and the potato tubers and possible plant residues are directed to the conveyors and elevators of the storage area. At the end of the device, the plant residue separating system is installed, which separates the plant residue and pours it onto the field surface. Because the device guides the lumps and possible stones of the same size as a potato into the tank, they must be separated from the potato with a tool. In some devices, this operation is done by a worker, and in advanced devices, it is done by a special mechanism designed for this operation. In some machines, potatoes are done by a worker, and in advanced machines, it is done by a special mechanism designed for this purpose.

Separating lumps from potatoes by manual and automatic methods

In some machines, the potatoes are directed to a special tank, and in other types, they are transported by another conveyor into the conveyor that moves parallel to the machine in the field.

Ready to operate potato harvesting machines

1- Take the potato can from the student.

2- Check the gearbox oil, if its level is low, add enough oil to it.

3-Grease all the grease fittings, such as the grease fittings of the drive disc bearing, the axle bearing of the wheels, etc., once or twice a day.

4- Repair or replace worn blades.

5- Oil the conveyor chain.

6- Replace or repair worn parts (belts, chains, etc.).

7- Unscrew the car.

8- Inspect all protective plates and make sure they are firmly in place.