Combine settings

Javid Kesht Leyzeri Co.Ltd (Mardani Trading)

The most important settings that a combine driver is involved with and will have access to from his location are:

Settings related to cutting and feeding unit

Settings related to the threshing unit

Cleaning unit settings

A) Settings related to the cutting and feeding unit:

The settings of this part, in addition to adjusting the cutting shoulder parts, include: adjusting the cutting height, leveling the platform, adjusting the position of the carousel propeller and adjusting the speed of the carousel propeller.

Adjustment of cutting height (height of the cutting platform from the ground):

This height, which can be adjusted from the driver's seat, should be made so that, on the one hand, it can guide the shortest clusters into the platform, and on the other hand, it should not be so low as to lift dirt and gravel from the ground. Also, it should not be so low that it imposes additional load and feed on the combine. In other words, adjust the cutting height according to the product conditions.

Cutting height adjustment indicator

When the platform is placed on the ground, the upper indicator degree of option 2 in the above figure shows zero, and as soon as the platform rises, its height is shown.

To adjust the height indicator of the platform, the iron strap with the hole option 1 in the picture above is used by moving the holes.

Checking the level of the platform:

The platform should be placed parallel to the front axle for this purpose:

1- Park the combine on a flat surface (asphalt surface).

2-Make sure that the air of the front wheels is adjusted correctly.

3- Raise the platform completely.

4- Measure the height from the ground on both sides of the platform.

Measuring the level of the platform

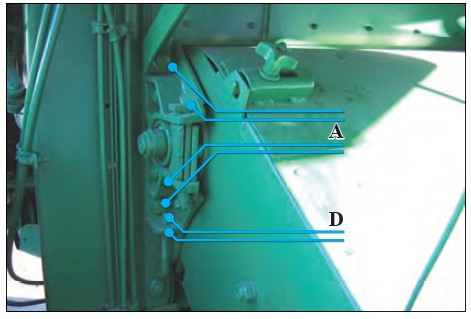

5- To adjust the platform horizontally, loosen all four screws A and tighten screws A and nut D after adjusting the device horizontally using nut D.

Platform leveling screws

Speed of the propeller:

The propeller speed depends on the density and condition of the product and when it is right the product falls directly into the cutting platform. The low speed of the propeller causes the product to fall due to the product falling in front of the cutting blade. High propeller speed is also associated with the following consequences:

The seeds fall out due to impact with the propeller.

Throwing the cut product on the ground.

Compressing the product instead of cutting it.

Wrapping the cut product around the propeller.

The speed change of the bumper is done by lever A in the figure below.

Carousel propeller speed adjustment lever

In a standing product, the speed of the propeller can be equal to or slightly higher than the speed of the combine, but in a lying product, the speed of the propeller should be about 25% higher than the speed of the combine.

Adjusting the position of the carousel propeller:

The position of the carousel can be adjusted horizontally and vertically with respect to the cutting shoulder.

To adjust the propeller forward or backward (horizontal), after removing pin A in the figure below, move the propeller on its carriers as desired, then tighten the propeller belt (usually the pin is placed in the fifth hole)

Adjusting the position of the carousel propeller

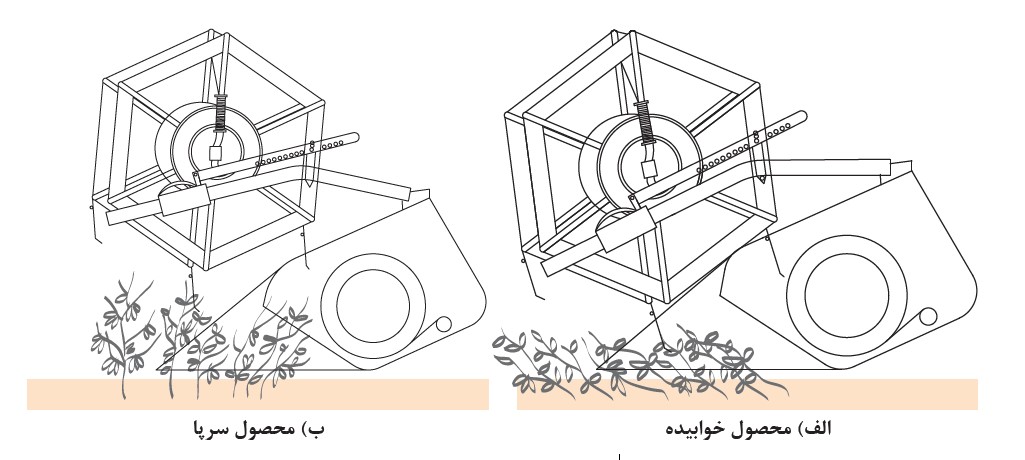

Pick-up reel is used to harvest the tilled crop (lying on the ground).

To adjust the finger carousel, it should be about 20 to 30 cm in front of the blades (horizontally) and its vertical position (propeller height) should be lowered so that the shoulder fingers touch the processed product and lift from the ground and in upright products, the fingers of the carousel should touch the stem from the bottom of the cluster.

The position of the carousel relative to the cutting blade

The fingers of the carousel should be parallel and the distance between them should be the same in order to avoid the rotation of the product with the propeller.

The height of the carousel (vertical position) also changes according to the product conditions. The propeller tubes must contact the sub-clusters of the crop and keep them away from the auger (cylinder) until it is cut. The low height causes the product to wrap around the propeller.

Adjusting the height of the bumper propeller is done through auxiliary jacks located on the sides of the outer walls of the platform.

Carousel height adjustment hydraulic jack

If the propeller does not go up and down uniformly, the reason is that there is air in the hydraulic system and it should be vented from the right jack. For this purpose, screw A should be loosened and the stopper should be raised, keep it in the same position for a few seconds until the oil without air comes out of the screw, and then tighten the screw.

b) Settings related to the crushing unit:

In the setting of this unit, two important factors, the distance between the hammer and anti-hammer and the speed of the hammer, play a decisive role. The distance between the knocker and the anti-knock in the front part can be adjusted between 8 and 34 mm, in this case the said distance in the rear part is equal to 4-17 mm. The amount of this distance is different for different products. Adjusting the beater speed is done when it is rotating. The hammer speed can be adjusted between 150-1150 rpm. This setting can be changed from inside the driver's cabin.

Adjusting the distance of the hammer

For small grain plants, the speed of the thresher is high and the distance between the thresher and the anti-thresher is small.

For large grain plants, the speed of the thresher is low and the distance between the thresher and the anti-thresher is relatively larger.

c) settings of the cleaning unit in the combine:

The most important settings of this unit include setting the fan wind and setting the meshes (holes) of the sieves.

Adjusting fan wind: It is important to accurately adjust the amount of wind in order to drive the straw over the sieves and also to obtain clean grain. As a result of the high intensity of the wind flow and also its lack, the grain loss increases, therefore the amount of the wind flow intensity should be adjusted according to the type of product.

The speed of the wind fan is mechanically adjusted by a lever located at the rear of the combine and on its left side. The speed range of the fan is between 320 and 1120 rpm.

Fan speed adjustment lever

To adjust the speed of the wind fan, it is done in this way that first the wind speed of the fan is stabilized at the recommended speed and gradually it is increased and the results are checked. This process is continued until the stage where the wind speed of the fan is so high that it throws the seeds out from the back of the combine. The speed before this step will be the optimal speed for cleaning that particular type of product.

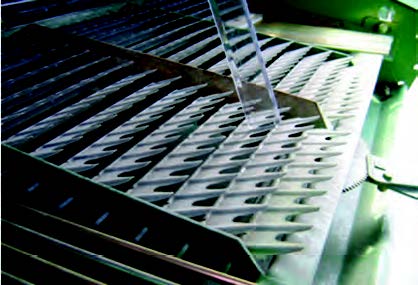

Adjusting the aperture of the sieves: The aperture (optical) of the sieves should be adjusted based on the values given in the driver's manual.

Too much opening of the meshes of the upper sieve (sieve) will cause overload in the sieve and too much closing of the meshes will cause some of the uncleaned product to come out of the combine.

The lever for adjusting the opening of the sieves

Too much closing of the meshes of the lower sieve to the addition of straw and extra straw in the helix of unbeaten, finished bunches, on the other hand, opening too much as suggested causes straw and fine straw to be seen in the storage tank.

Eye sizes mean the distance between parallel planes tangent to the tabs. This means that the size of the perpendicular distance between two adjacent tongues is considered an eye size and the measurement from the end edge of one tongue to the edge of the other tongue is not correct.

Steps to adjust the combine

1- Adjust the distance between the knocker and the anti-knocker.

2- Change the holes of the sieves.

3- Turn on the combine.

4- Adjust the position of the carousel in different modes.

5- Change the speed of the carousel.

6- Change the beater speed.

7- Set the fan speed in different modes.