Construction and operation of grain combine-threshing unit

Javid Kesht Leyzeri Co.Ltd (Mardani Trading)

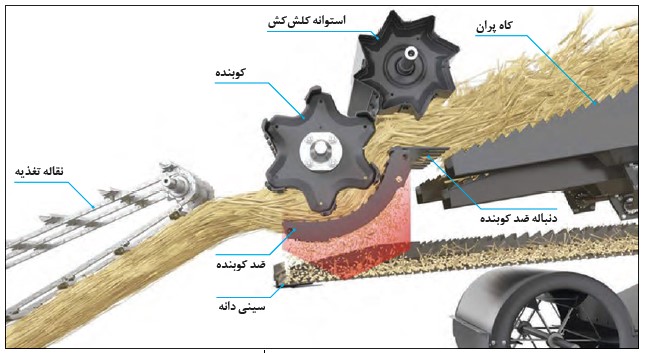

The threshing unit in every combine is considered the heart of the machine. Ninety percent of the seeds are separated from the clusters in this part and poured into the beaten seeds tray to be transferred to the sieve and sieve for cleaning.

This part consists of two knocking and anti-knocking agents (cylinder and sub-cylinder). The anti-hammer is fixed and the hammer has a rotary motion. The beater pulls the product from the feeding unit to the space between the beater and anti-beater. Due to the movement of the beater on the anti-beater, the seeds are separated from their clusters.

Separated seeds and some of the chopped straw and stubble fall through the anti-knock holes on the seed tray.

Unseparated seeds and remaining straw and stubble after passing through the under-cylinder trail (under-cylinder trail fingers) are guided on the straw hopper.

In order to prevent straw and stubble from returning to the threshing unit, a rotating part (stub cylinder) has been used.

Hammer unit

In the front part of the anti-crusher, a stud-shaped plate called a stone catcher is used to prevent stones from entering the clogging unit.

stone catcher

In general, there are three types of knockers and suitable anti-knockers as follows:

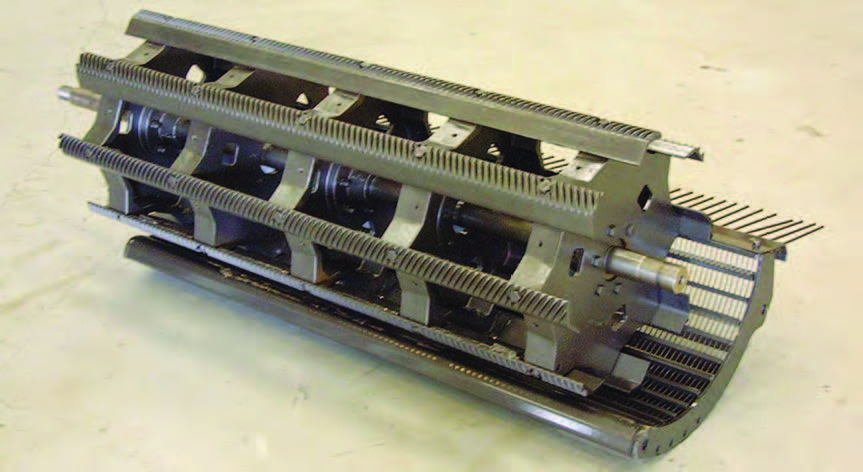

Hammer and anti-hammer:

This type is the most common thresher used in most combines. It is usually used for threshing crops such as corn, oil beans, wheat and barley.

Hammering and anti-hammering

Impact and anti-impact wear:

It is mostly used for small seeds such as clover and alfalfa.

Abrasion hammer

Knocker and anti-knock hammer:

This type is used for threshing the seeds of products that are difficult to thresh, such as rice and all kinds of edible beans.

Hammer knocker and anti-knock