Construction and operation of grain combine-feed cutting unit

Javid Kesht Leyzeri Co.Ltd (Mardani Trading)

A combine is used in one-step harvesting of grain. In agricultural culture, this word refers to a machine that performs all the actions that are done separately with grain harvesting machines together and at the same time. These actions include:

The act of harvesting, collecting, and transferring the product to the threshing unit

The act of pounding the product

Separating the seeds from the bunch and straw

Cleaning the seeds

Transferring the cleaned seeds to the tank or bagging them

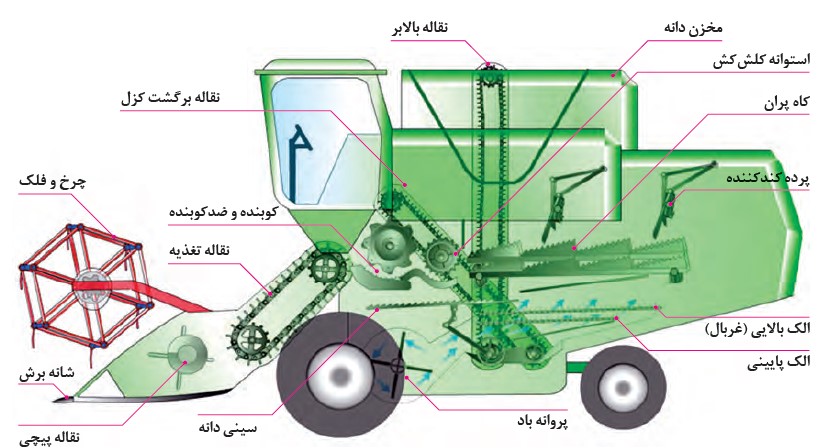

Grain combine components

Due to the fact that the combine performs five main actions in harvesting the product, it has different units, each of these actions is performed by one unit of the combine.

1- Cutting and feeding unit:

This unit harvests the product, collects it and transfers it to the threshing part by means of a conveyor. One of the features of today's combines is that by changing the cutting and feeding unit, they can be used to harvest different grains.

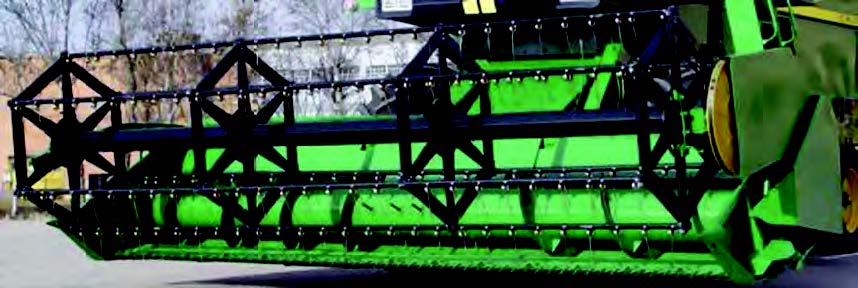

Common cutting unit of the combine (platform for wheat, barley, rice and canola):

The most common cutting and feeding unit is for harvesting wheat and barley, which consists of the sections of dividing nose, wheel and carousel (stubble propeller), harvester comb, screw conveyor and feeding conveyor (feeder house).

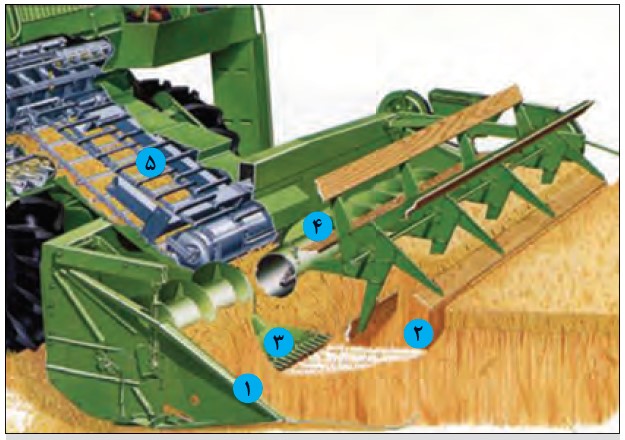

1 dividing nose, 2 carousels, 3 harvester combs, 4 screw conveyors, 5 feeding conveyors

The passage of grain in the cutting and feeding unit

Common combine platform

As the combine moves forward, the dividing nose separates a row of the product according to the width of the harvester, the carousel is located above the cutting shoulder, and with its rotational movement, it bends the product towards the cutting shoulder, and while the product is moved by the shoulder It is cut and harvested. As a result of the advance of the combine harvester, the harvested product falls on the floor.

The screw conveyor has two-way spiral blades that bring the harvested product from the sides to the middle part with its rotational movement and guide the product to the feeding conveyor by means of fingers located in the middle part of the conveyor.

Screw conveyor cutting unit

The feeding conveyor is in the form of corners that are mounted on a chain and raise the product at the bottom of its chamber and deliver it to the threshing unit.

Combine feed conveyor

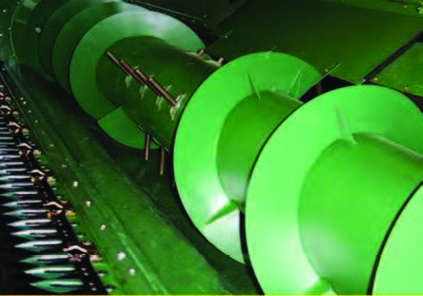

This platform can be used with a finger carousel to harvest rice and milled products.

The platform is equipped with a finger carousel

Corn platform

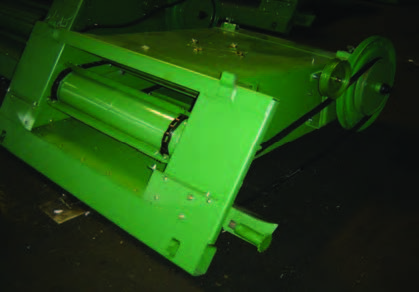

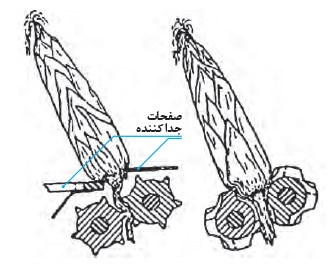

Cutter cob rollers

Corn harvesting platform:

When harvesting corn with a combine harvester, a mechanism is needed to separate the ears from the stalks in order to separate the corn kernels from the wood by the threshing cylinder.

The separation of the cob from its stem is formed in such a way that first the front collecting shoes (variable from 2 to 12 rows in the corn combine) are placed between the rows of cultivation and as the combine moves forward, the corn stalks are placed between the shoes. They are stuck and pulled down by the separating rollers. As a result, the cobs do not pass through the space between the two shoes and the cob folds and are separated from the stem. It is at this time that the collecting chains lead the cobs to the area of the feeding screw conveyor. After going through these steps, they go to the feeding conveyor and then to the guide threshing cylinder 12 and 13.

How the cob is separated from the stem by the rollers