براي نخ كردن بیلر مي توان از نخ های نايلوني كه از تابیدن الیاف نایلونی به دست مي آیند يا نخ های ليفي كه از تابيدن الیاف گیاهی (مانند: کنف، سیسل و....) تهیه مي گردد، استفاده كرد.

براي نخ كردن بیلر مي توان از نخ های نايلوني كه از تابیدن الیاف نایلونی به دست مي آیند يا نخ های ليفي كه از تابيدن الیاف گیاهی (مانند: کنف، سیسل و....) تهیه مي گردد، استفاده كرد.

برای دریافت اطلاعات در مورد دستگاه بسته بندی علوفه و دستگاه سیلاژ علوفه، قیمت خرید دستگاه بسته بندی علوفه و مشاوره خرید کافی است با مدیر فروش شرکت جناب آقای مهندس مردانی با شماره همراه 09121537060 تماس بگیرید و یا از طریق پیام رسان ایتا و واتساپ به ایشان پیام ارسال نمایید.

کلمات کلیدی: قیمت دستگاه سیلاژ علوفه,قیمت دستگاه بسته بندی علوفه,فروش دستگاه سیلاژ علوفه,فروش دستگاه بسته بندی علوفه,خرید دستگاه سیلاژ علوفه,خرید دستگاه بسته بندی علوفه,دستگاه بسته بندی علوفه,دستگاه سیلاژ علوفه,دستگاه سیلاژ ذرت علوفه ای,دستگاه سیلاژ تفاله مالت,دستگاه سیلاژ ذرت,دستگاه بسته بندی ذرت علوفه ای,قیمت دستگاه سیلاژ ذرت علوفه ای,قیمت دستگاه سیلاژ,فروش دستگاه سیلاژ,دستگاه سیلاژ تفاله چغندرقند,دستگاه بسته بندی تفاله چغندرقند ,دستگاه سیلاژ یونجه,قیمت دستگاه سیلاژ یونجه,فروش دستگاه سیلاژ یونجه,قیمت دستگاه سیلاژ مالت علوفه ای,خرید دستگاه سیلاژ یونجه

مروزه در كشورهاي مدرن از نخ های نايلوني به دليل مشكلات بازيافتي و همچنين اشکالاتی که در جهاز هاضمه حیوان بعد از بلعیده شدن ایجاد مي کند، کمتر استفاده مي شود.

نخ نایلونی بیلر

نخ کنفی بیلر

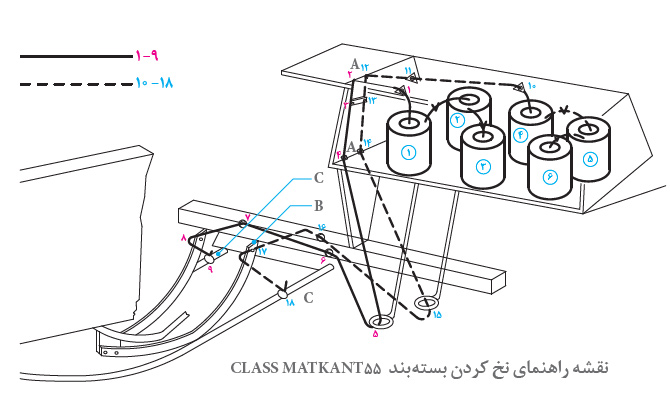

از آنجا كه الگوي نخ كردن بسته بندها متفاوت است معمولاً نقشه راهنماي نخ كردن روي درپوش محل ذخيره نخ ماشين توسط شركت های سازنده ارائه مي شود.

نقشه راهنماي نخ كردن بسته بند 55 CLASS MATKANT

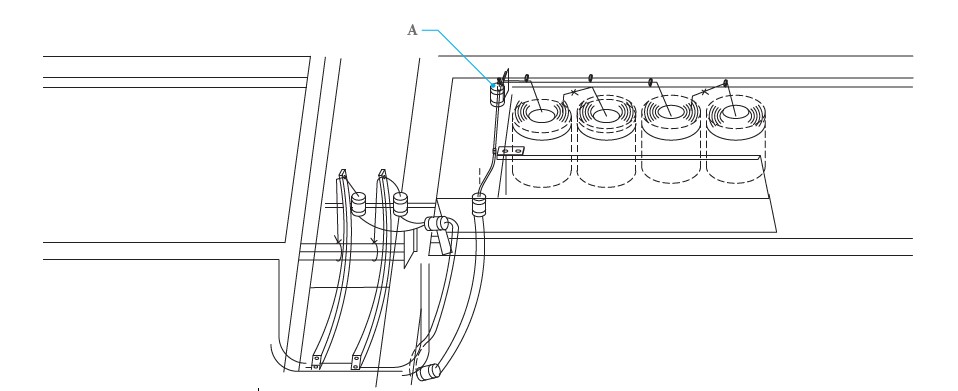

نقشه راهنماي نخ كردن بسته بند مدل 3690 برچين كار

مراحل انجام نخ کردن بیلر

1-جنس مناسب نخ را برای واحد نخ بندی انتخاب کنید.

2-کلاف های نخ را در مخزن نخ در محل تعیین شده طوری قرار دهید که بالای کلاف ها که مشخص شده، به سمت بالا باشد.

3-کلاف ها را دو به دو با گره زدن به هم متصل کنید به طوری که سرنخ انتهایی و بیرونی بسته ای که مورد استفاده واقع شده با سرنخ داخلی و مرکزی کلاف رزرو وصل شود.

گره باید به اندازه ای باشد که بتواند از محل راهنمای نخ عبور کند. قبل از گره زدن انتهای نخ های کنفی را مرطوب کنید و اضافه دو سر نخ را از نزدیکی گره قطع کنید. نخ های پلاستیکی را بدون مرطوب کردن گره بزنید.

گره زدن نخ كنفي

گره زدن نخ نايلوني

4-سرنخ را از مرکز بسته نخ بیرون آورده و از راهنمای نخ (A) عبور دهید. سپس هر دو نخ را از بین دو صفحه فشار دهنده که تنظیم کننده کششی نخ مي باشند رد کنید.

5- درحالی که سوزن ها در جایگاه خود قرار دارند اصطلاحاً موقعیت قبل از حرکت رو به بالا و بدون حرکت آن را که قبلاً تنظیم شده جایگاه گویند( مطابق نقشه راهنماي ماشين، كيي از نخ ها را از مسيرهاي مشخص شده عبور دهيد.

6-سرنخ را در نقطۀ (C) روی حفاظ سوزن ها گره بزنید.

7-موارد قبلی را برای نخ دوم و سوزن آن تکرار کنید.

تنظيم كننده كشش نخ

مسير نخ كردن بیلر و جايگاه سوزن

توجه كنيد نخ ها به دور یکدیگر تابیده نشده باشند.

8-اهرم چرخ ستاره اي را آزاد كنيد.

9-چرخ ستاره ای را در حالتی قرار دهید كه کلاچ دستگاه گره زن بتواند کار خود را شروع کند.

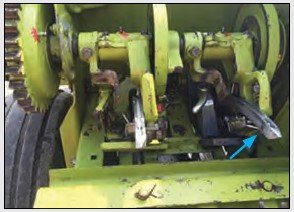

اهرم چرخ ستاره اي بیلر

10-چرخ لنگر را در جهت عکس عقربه های ساعت بچرخانید تا سوزن ها بالا آمده و نخ را تحويل نخ گير دهند.

تحويل نخ به نخ گير

11-چرخش فلايويل را ادامه دهيد تا سوزن ها مجددا به جایگاه خود بر گردند.

12-اضافی نخ را از روی شاسی جدا کنید. اکنون دستگاه از نظر وضعیت نخ آماده بسته بندی و کار مي باشد.

هيچ گاه قبل از توقف كامل ماشين و خاموش كردن تراكتور اقدام به نخ كردن آن نكنيد.

از رها كردن نخ های اضافي در محيط زيست اجتناب كنيد.

جهت مشاهده تصاویر محصولات بیلر بر روی لینک زیر کلیک فرمایید:

برای دریافت اطلاعات در مورد دستگاه بسته بندی علوفه و دستگاه سیلاژ علوفه، قیمت خرید دستگاه بسته بندی علوفه و مشاوره خرید کافی است با مدیر فروش شرکت جناب آقای مهندس مردانی با شماره همراه 09121537060 تماس بگیرید و یا از طریق پیام رسان ایتا و واتساپ به ایشان پیام ارسال نمایید.

کلمات کلیدی: قیمت دستگاه سیلاژ علوفه,قیمت دستگاه بسته بندی علوفه,فروش دستگاه سیلاژ علوفه,فروش دستگاه بسته بندی علوفه,خرید دستگاه سیلاژ علوفه,خرید دستگاه بسته بندی علوفه,دستگاه بسته بندی علوفه,دستگاه سیلاژ علوفه,دستگاه سیلاژ ذرت علوفه ای,دستگاه سیلاژ تفاله مالت,دستگاه سیلاژ ذرت,دستگاه بسته بندی ذرت علوفه ای,قیمت دستگاه سیلاژ ذرت علوفه ای,قیمت دستگاه سیلاژ,فروش دستگاه سیلاژ,دستگاه سیلاژ تفاله چغندرقند,دستگاه بسته بندی تفاله چغندرقند ,دستگاه سیلاژ یونجه,قیمت دستگاه سیلاژ یونجه,فروش دستگاه سیلاژ یونجه,قیمت دستگاه سیلاژ مالت علوفه ای,خرید دستگاه سیلاژ یونجه