Knife Cutter mower

Javid Kesht Leyzeri Co.Ltd (Mardani Trading)

Knife Cutter mower

Conventional Knife Cutter mowers may be tractor-powered or self-propelled. In addition, there are types of small movers whose power is supplied through the tiller.

Of course, currently the most common type of Knife Cutter mower used is the type mounted on the back of the tractor.

Types of shoulder mowers: tiller mowers, self-propelled mowers, tractor-backed mowers

In general, the principles of reaping in comb mowers are in accordance with the function of scissors, with the difference that in this type of mowers, one edge of the scissors (blade) is movable and the other edge of the scissors (finger) is fixed.

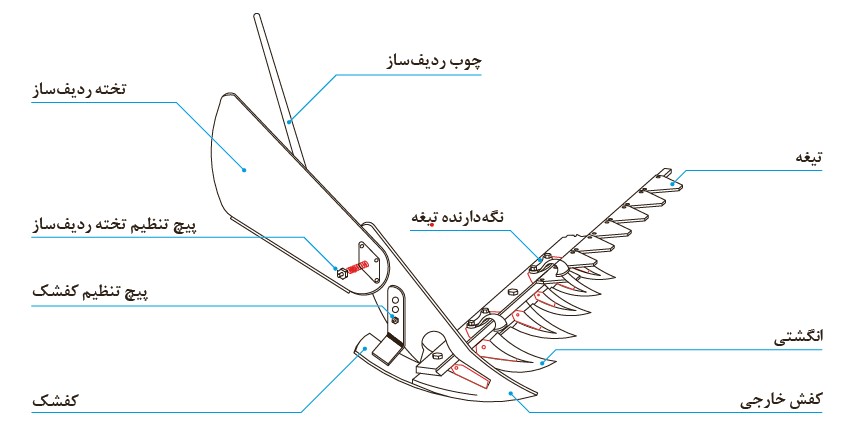

Position of finger and blade in Knife Cutter mover

The trapezoidal blades cut the product by moving back and forth against the fingers. To adjust the vertical distance between the blade and the plate or finger blade, metal parts called clamps or blade holders are screwed on the trunk at several different points with equal distances and prevent the vertical laxity of the set of blades.

fastening mower

The blades are riveted on a metal band called the back strap, and together with the fingers, inner and outer shoes, trunk, clip and rowing board, they form the cutting Knife Cutter.

The set of Knife Cutter blades are carried on both inner and outer shoes.

The shoe that is close to the tractor is called the inner shoe and the one that is further away from the tractor is called the outer shoe. Under the shoe, there is a piece called heel or shoe, which is used to adjust the cutting height.

Comb cutter components, Knife Cutter mower

The separating rod, which is located in front of the inner shoe, guides the fodder towards the cutting machine.

A wooden board called rowing board is connected to the back of the outer shoe and guides the cut fodder to the tractor.

At the end of the rowing board, there is a wooden rod called the rowing stick, and it prevents the long stems from falling out.

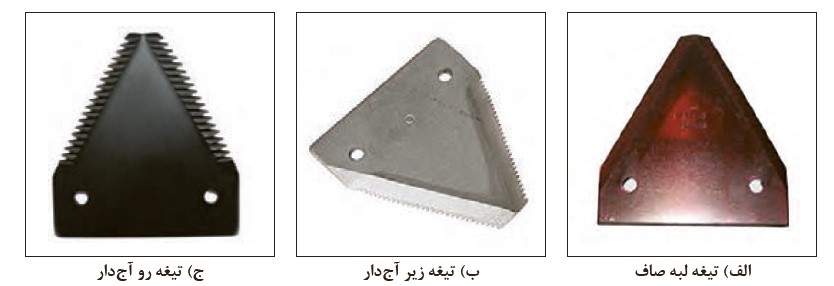

The blades have different types such as smooth edge, ridged and sub-ridged. The smooth edge blades are used to harvest soft fodder such as fodder soybeans, clover and spruce. Grooved and undergrooved blades are used for threshing wooden and semi-wooden products such as grain and wood.

Types of Knife Cutter mower blades

The blades form only one cutting edge, the other edge is formed by the finger plate (blade). Among the other tasks of the finger, we can mention sorting the fodder for cutting and protecting the blade. The finger cover prevents the stems from lying on the finger.

Common types of finger blade Knife Cutter mower

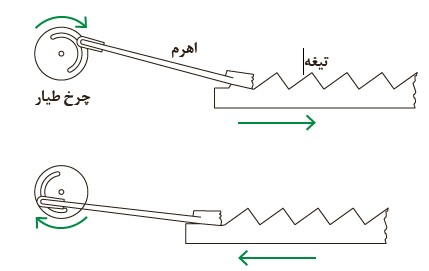

The required force of the Knife Cutter is provided by the power transmission axis of the tractor and is delivered to the cutting Knife Cutter by the power transmission unit of the motor. In the power transmission unit, there is a piece of wood called a dowel, one end of which is mounted on the off-center plate and the other end of which is mounted on the cutting unit.

The image of the wooden piece in the power transmission unit of the Knife Cutter mower (hand lever)

By this part and its off-center location on the rotating surface, the rotational movement of the power transmission axis is converted into the reciprocating movement of the blade.

Converting rotational movement to reciprocating movement in the Knife Cutter mower

The back and forth movement of the blades causes the fodder to be sorted, the sorted fodder is left behind the machine on the ground. The sorted fodder is directed to the back of the tractor by the rowing board. As a result, the location of the tractor wheels will be determined to move during the harvesting of the next row.

In modern motors, a vibrating drive system (hydraulic mechanics) is used to convert rotary motion into reciprocating motion.

Knife Cutter mower with vibration drive system

In some Knife Cutter mowers, a type of safety clutch is used between the motor's power transmission axis and the belt and pulley or blade drive gearbox. The job of the safety clutch is to stop the movement of the blade if a hard obstacle gets stuck inside the cutting Knife Cutter so that the parts of the Knife Cutter are not damaged. The operation of the safety clutch is accompanied by a clicking sound, that's why it is known as a ratchet clutch.

Click on the following links to view pictures and videos of the hay cutting product (mower):

The image of TINAZ Turkey hay cutting types

The video of TINAZ Turkey hay cutting types