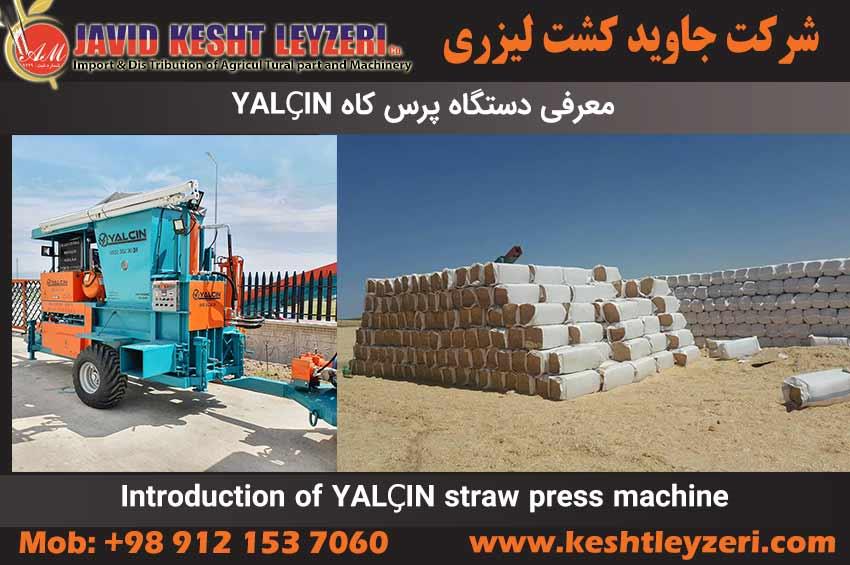

دستگاه پرس کاه شرکت YALÇIN در ترکیه با استفاده از فناوری هیدرولیک، نیروی کار کاهبر را به صورت قالبی فشرده کرده و بدون نیاز به سیستم بستهبندی، بستهبندی کاه را انجام میدهد. این دستگاه به توان ۹۰ اسببخاری تراکتور، برق و ژنراتور کار میکند و باعث صرفهجویی در هزینه حمل و انبار کاه میشود. با ظرفیت تولید ۴-۵ تن در ساعت، این دستگاه دارای سیستمهای خنککن هوا و روغن، کمپرسور هوا، و گارانتی تولیدی برای ۱۰۰۰ تن میباشد.

لیست مطالب این بخش:

- دستگاه پرس کاه شرکت YALÇIN ترکیه: دستگاه بستهبندی کاه چیست و چه کاربردی دارد؟

- سیستم کارکرد با تراکتور، برق و ژنراتور دستگاه پرس کاه YALÇIN چیست؟

در ادامه مطالب فوق بررسی خواهند شد.

برای خرید و دریافت اطلاعات بیشتر از دستگاه پرس کاه YALÇIN، شما میتوانید با مدیر فروش شرکت جاوید کشت لیزری، آقای مهندس مردانی (شماره تماس: 09121537060) تماس حاصل نمایید و یا از طریق پیام رسانهای ایتا و واتساپ به ایشان پیام ارسال نمایید. این نمایندگی انحصاری، بهترین خدمات و تجربه خرید، به عنوان یک گارانتی اعتباری و کیفیتی به مشتریان خود ارائه می دهد.

نیاز به مشاوره یا پرسش دارید؟

اگر درباره دستگاه پرس کاه و دستگاه بسته بندی ذرت علوفهای یا دستگاه سیلاژ ذرت علوفهای سوالی دارید یا میخواهید بهترین مدل را برای کشاورزی خود انتخاب کنید، همین حالا با ما تماس بگیرید یا از طریق واتساپ پیام دهید.

کلمات کلیدی: دستگاه پرس کاه,نمایندگی فروش دستگاه پرس کاه,نمایندگی دستگاه پرس کاه,قیمت دستگاه پرس کاه,شرایط فروش دستگاه پرس کاه,فروش دستگاه پرس کاه,دستگاه پرس کاه YALÇIN,دستگاه بسته بندی کاه,نمایندگی انحصاری شرکت YALCIN,دستگاه پرس کاه نرم,نمایندگی دستگاه پرس کاه نرم,نمایندگی شرکت YALCIN,خرید دستگاه پرس کاه,پرس کاه نرم,دستگاه YALÇIN,پرس کاه با دستگاه YALÇIN,بستهبندی مواد زراعی کاه,دستگاه برقی پرس کاه,بستهبندی کاه اتوماتیک,دستگاه تمام اتوماتیک پرس کاه,نگهداری دستگاه پرس کاه,عیب یابی دستگاه پرس کاه,بسته بندی اتوماتیک پرس کاه,دستگاه پرس کاه اتوماتیک,سیستم حرکتی دستگاه پرس کاه,منابع انرژی دستگاه پرس کاه,سیستم بسته بندی دستگاه پرس کاه,مزایای دستگاه پرس کاه,دستگاه پرس کاه و کلش,گزارش فنی دستگاه پرس کاه,مشخصات دستگاه پرس کاه,سامانه حرکتی پیشرفته در دستگاه پرس کاه,موتور Gamak در دستگاه پرس کاه,ابعاد و وزن دستگاه پرس کاه YALÇIN,عملکرد پرس کاه هوشمندYALÇIN

نمایندگی و قیمت فروش دستگاه پرس کاه YALÇIN: سیستمهای کنترل، عیبیابی و نکات نگهداری اجزاء دستگاه

دستگاه پرس کاه شرکت YALÇIN ترکیه: دستگاه بستهبندی کاه چیست و چه کاربردی دارد؟

دستگاه بستهبندی کاه یا همان دستگاه پرس کاه (saman paketleme makinası) با وارد کردن کاه به صورت پودری به یک قالب خاص، سهولت در محل، زمان و نیروی کار فراهم میکند. این دستگاههای بستهبندی کاه، از جدیدترین فناوریهای کشاورزی استفاده کرده و با کاهش نیروی کار، به شما در همگرایی هم زمان از نظر زمان و هزینه کمک میکند. دستگاههای ما که به صورت هیدرولیک کار میکنند، کاه را به صورت قالبی بیرون میآورند و در انبار کردن، حمل و نقل کاه نیز نقش مهمی دارند. این دستگاهها برای کاهش بار کاری کشاورزان ساخته شدهاند و کار ۱۰ نفر را با موفقیت انجام میدهند. در حوزه بینالمللی، شرکت Yalcyn به عنوان پیشرو در بستهبندی کاه و پرس کاه در ترکیه و جهان ادامه میدهد.

فروش ویژه دستگاه پرس کاه

سیستم کارکرد با تراکتور، برق و ژنراتور دستگاه پرس کاه YALÇIN چیست؟

- حداقل باید از یک تراکتور با توان ۹۰ اسببخار و میل ۵۴۰ دور در دقیقه استفاده شود.

- دستگاه باید با توجه به شرایط آب و هوا در محل موقعیت یابی شود.

- دستگاه که کاه را به نسبت ۱/۳ فشرده کرده و بدون نیاز به سیستم بستهبندی با سیم یا بندهای دیگر، بستهبندی انجام میدهد.

- باعث صرفهجویی ۱/۳ در هزینه حمل و انبار کاه میشود.

- با استفاده از کارگران کم، به حداکثر بهره وری دست یافته میشود.

- دستگاه قادر است با استفاده از یک ژنراتور حداقل ۱۶۵ کیلووات و یک تراکتور حداقل ۹۰ اسببخار به سه روش مختلف کار کند.

- هنگام کار با تراکتور، با توجه به توان ۲۰ کیلوواتی ژنراتور، انرژی مورد نیاز برای سیستم (باند، هلیکس، نور، کمپرسور) تأمین میشود. نیازی به انرژی اضافی ندارد.

- تغذیه کاه به دستگاه با کمک یک هلیکس انجام میشود.

- این عملیات با استفاده از سیستم برق PLC و نرمافزار (Yazılım) به صورت خودکار انجام میشود.

- با کاهش مصرف غیرضروری کاه، به اقتصاد کمک میکند.

- ابعاد بستهبندی باله دستگاه: ۷۵x۳۰x۳۵ سانتیمتر است.

- موتور دستگاه با توان ۳۷ کیلووات مجهز شده است.

- تراکتور سازگار است (الکتریکی ژنراتور تولید کننده ۲۰ کیلووات).

- ظرفیت دستگاه بین ۲۵ تا ۳۵ کیلوگرم متغیر است (بسته به نوع مواد).

- دستگاه توانایی تولید یک بسته در ۲۱ ثانیه را دارد (حدود ۴-۵ تن در ساعت).

- دستگاه دارای سیستم خنککن هوا و سیستم خنککن روغن است.

- کمپرسور هوا با ظرفیت ۱۰۰ لیتر نیز وجود دارد.

- گارانتی تولیدی دستگاه برای ۱۰۰۰ تن است.

- الکتریک و ولوهای هیدرولیک دستگاه از گارانتی مستثنی هستند.

- نصب اولیه توسط خدمات پس از فروش تحت گارانتی انجام میشود، اما سرویسها و درخواستهای بعدی با هزینه انجام میشود.

- سیلندر خروجی مواد قابل انعطاف است.

- در صندوق ابزار دستگاه، کلید لوله، المنچ، چکش و همچنین مهره متصل به میخ وجود دارد.

- پشتیبانی از جلوی دستگاه حاوی یک چادر سایه است.

- سیستم نورپردازی شب (پروژکتور) شامل ۴ عدد است.

- ساختار بدنه از جنس ST ۵۲ و مقاوم در برابر سایش است.

- سیستم هیدرولیک با ولو NG۲۵ دارای حرکت است.

- سیستم الکتریکی به شکل PLC است.

- شمارنده تعداد باله تولید شده در دستگاه وجود دارد.

- اندازه چوبی ۷۰x۱۲۰ سانتیمتر است.

- بلوک بدنه یکپارچه مانو در دستگاه وجود دارد.

- ۴ پای ثابت نیز در دستگاه وجود دارد.

برای خرید و دریافت اطلاعات بیشتر از دستگاه پرس کاه YALÇIN، شما میتوانید با مدیر فروش شرکت جاوید کشت لیزری، آقای مهندس مردانی (شماره تماس: 09121537060) تماس حاصل نمایید و یا از طریق پیام رسانهای ایتا و واتساپ به ایشان پیام ارسال نمایید. این نمایندگی انحصاری، بهترین خدمات و تجربه خرید، به عنوان یک گارانتی اعتباری و کیفیتی به مشتریان خود ارائه می دهد.

گزارش فنی بررسی و قیمت دستگاه پرس کاه YALÇIN

نمایندگی دستگاه پرس کاه: مشخصات فنی، عملکرد و ارزیابی دستگاه پرس کاه YALÇIN

نمایندگی فروش دستگاه پرس کاه YALÇIN : سیستم حرکتی، منابع انرژی، سیستم بستهبندی و مزایای دستگاه

نمایندگی و قیمت فروش دستگاه پرس کاه YALÇIN: سیستمهای کنترل، عیبیابی و نکات نگهداری اجزاء دستگاه

قیمت دستگاه پرس کاه YALÇIN: اجزاء و اصول عملکرد دستگاه