دستگاه با سیستم کنترل PLC برای تنظیمات دقیق و بهرهوری بالا ارتقاء یافته است. نگهداری منظم و بررسی دورهای اتصالات جلوگیری از نشتی و کاهش خطرات را تضمین میکند. حفظ سطح روغنها و آموزش بهینه به کاربران برای ایمنی و استفاده صحیح از دستگاه، دوام و بهرهوری دستگاه را افزایش میدهد.

لیست مطالب این بخش:

نکات نگهداری اجزاء دستگاه پرس کاه YALÇINچیست؟

سیستمهای کنترل و عیبیابی دستگاه پرس کاه YALÇIN چیست؟

نکات تکمیلی در عیبیابی و نگهداری دستگاه پرس کاه YALÇIN چیست؟

در ادامه مطالب فوق بررسی خواهند شد.

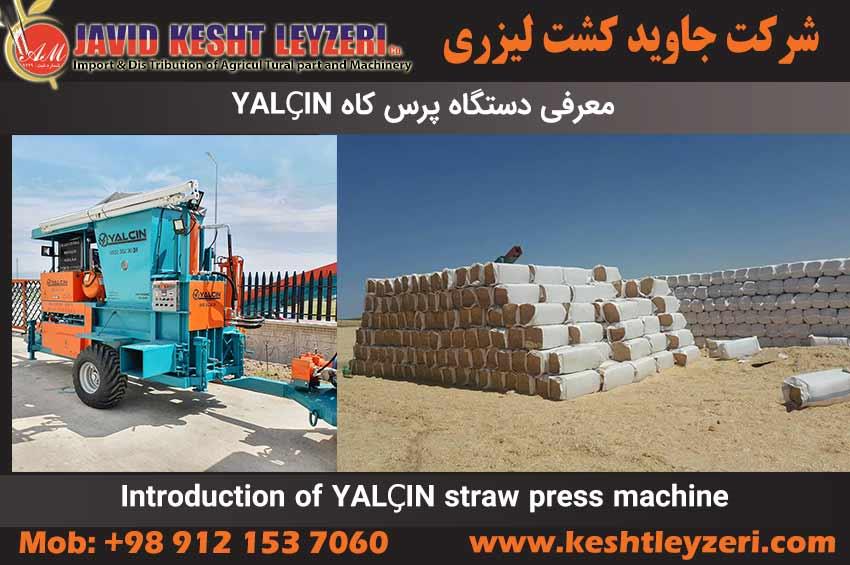

برای خرید و دریافت اطلاعات بیشتر از دستگاه پرس کاه YALÇIN، شما میتوانید با مدیر فروش شرکت جاوید کشت لیزری، آقای مهندس مردانی (شماره تماس: 09121537060) تماس حاصل نمایید و یا از طریق پیام رسانهای ایتا و واتساپ به ایشان پیام ارسال نمایید. این نمایندگی انحصاری، بهترین خدمات و تجربه خرید، به عنوان یک گارانتی اعتباری و کیفیتی به مشتریان خود ارائه می دهد.

نیاز به مشاوره یا پرسش دارید؟

اگر درباره دستگاه پرس کاه و دستگاه بسته بندی ذرت علوفهای یا دستگاه سیلاژ ذرت علوفهای سوالی دارید یا میخواهید بهترین مدل را برای کشاورزی خود انتخاب کنید، همین حالا با ما تماس بگیرید یا از طریق واتساپ پیام دهید.

کلمات کلیدی: دستگاه پرس کاه,نمایندگی فروش دستگاه پرس کاه,نمایندگی دستگاه پرس کاه,قیمت دستگاه پرس کاه,شرایط فروش دستگاه پرس کاه,فروش دستگاه پرس کاه,دستگاه پرس کاه YALÇIN,دستگاه بسته بندی کاه,نمایندگی انحصاری شرکت YALCIN,دستگاه پرس کاه نرم,نمایندگی دستگاه پرس کاه نرم,نمایندگی شرکت YALCIN,خرید دستگاه پرس کاه,پرس کاه نرم,دستگاه YALÇIN,پرس کاه با دستگاه YALÇIN,بستهبندی مواد زراعی کاه,دستگاه برقی پرس کاه,بستهبندی کاه اتوماتیک,دستگاه تمام اتوماتیک پرس کاه,نگهداری دستگاه پرس کاه,عیب یابی دستگاه پرس کاه,بسته بندی اتوماتیک پرس کاه,دستگاه پرس کاه اتوماتیک,سیستم حرکتی دستگاه پرس کاه,منابع انرژی دستگاه پرس کاه,سیستم بسته بندی دستگاه پرس کاه,مزایای دستگاه پرس کاه,دستگاه پرس کاه و کلش,گزارش فنی دستگاه پرس کاه,مشخصات دستگاه پرس کاه,سامانه حرکتی پیشرفته در دستگاه پرس کاه,موتور Gamak در دستگاه پرس کاه,ابعاد و وزن دستگاه پرس کاه YALÇIN,عملکرد پرس کاه هوشمندYALÇIN

نکات نگهداری اجزاء دستگاه پرس کاه YALÇINچیست؟

در این مطلب به معرفی دقیقتر اجزاء اصلی دستگاه پرس کاه YALÇIN و نکات مرتبط با نگهداری خواهیم پرداخت.

فروش ویژه دستگاه پرس کاه

1. پیستونها:

- پیستونها بخش اساسی دستگاه هستند که با حرکت هیدرولیک، مواد زراعی را به فشردگی مطلوب فشرده و بستهبندی میکنند. اهمیت نظافت و روانی حرکت پیستونها در حین عملکرد به دقت بالا و کاهش خطرات مرتبط با نگهداری کمک میکند.

2. سیستم بستهبندی:

- سیستم بستهبندی اتوماتیک دستگاه یکی از ویژگیهای کلیدی آن است. برای حفظ عملکرد بهینه، تمیزی و دقت در نصب و عیبیابی این سیستم حائز اهمیت است.

3. سیستم کنترل PLC:

- نگهداری سیستم کنترل PLC نیز از اهمیت ویژهای برخوردار است. به روز نگهداری و اطمینان از کارکرد صحیح این سیستم، عملکرد دستگاه را بهبود میبخشد.

4. سیستم خنککننده:

- نظافت دورهای و تعویض منظم فیلترهای سیستم خنککننده از اهمیت بسیار زیادی برخوردار است. حفظ سلامت این سیستم به افزایش دوام و بهرهوری دستگاه کمک میکند.

5. نکات عمومی نگهداری:

- اطمینان از سطح روغنها و مایعات هیدرولیک و بهروز نگهداری آنها.

- بررسی دورهای اتصالات و مهرهها برای جلوگیری از نشتی و کاهش خطرات احتمالی.

- آموزش بهینه به کاربران در مورد نکات ایمنی و استفاده صحیح از دستگاه.

با رعایت نکات نگهداری و تعمیرات منظم، دستگاه پرس کاه YALÇIN به دوام و بهرهوری بیشتری خواهد رسید.

گزارش فنی بررسی و قیمت دستگاه پرس کاه YALÇIN

سیستمهای کنترل و عیبیابی دستگاه پرس کاه YALÇIN چیست؟

در این مطلب به معرفی سیستمهای کنترل و نحوه عیبیابی در دستگاه پرس کاه YALÇIN خواهیم پرداخت.

1. سیستم کنترل PLC:

- سیستم کنترل PLC در دستگاه پرس کاه YALÇIN باعث اتوماسیون و کنترل دقیق فرآیند بستهبندی میشود. در صورت بروز هر گونه مشکل یا نقص در این سیستم، عملکرد دستگاه قطع میشود. بنابراین، برنامهریزی عیبیابی دقیق از اهمیت بالایی برخوردار است.

2. سیستم هیدرولیک:

- سیستم هیدرولیک که با پیستونها هماهنگ است، نقش اساسی در عملکرد دستگاه دارد. عیبیابی دورهای در این سیستم، شامل بررسی نشتیها، سطح روغن، و عملکرد صحیح پمپها و ولوها میشود.

3. سیستم بستهبندی:

- در صورت مشکل در سیستم بستهبندی اتوماتیک، احتمال خطا در بستهبندی یا ایجاد مشکلات در حمل و نقل بستهها وجود دارد. بررسی دقیق اتصالات مکانیکی و تنظیمات سیستم بستهبندی از موارد حیاتی است.

4. سیستم خنککننده:

- اگر سیستم خنککننده به درستی عمل نکند، دمای دستگاه ممکن است افزایش یابد و این موضوع میتواند به کاهش کارایی و خطرات برای دستگاه منجر شود. عیبیابی در این سیستم شامل بررسی و تعویض فیلترها و تنظیمات بهینه میشود.

5. اجزاء مکانیکی:

- عیبیابی در اجزاء مکانیکی شامل بررسی و تنظیم اتصالات، لنگرها، و بلبرینگها است. هر گونه کمرنگی یا فرسودگی در این اجزاء میتواند عملکرد دستگاه را تحت تأثیر قرار دهد.

6. نگهداری منظم:

- انجام نگهداریهای منظم با توجه به دستورالعملهای تولید کننده از اهمیت بسیار زیادی برخوردار است. این شامل تعویض قطعات مصرفی، روانسازی قطعات مکانیکی، و تنظیمات کلی دستگاه میشود.

با ایجاد برنامه منظم عیبیابی و نگهداری، دستگاه پرس کاه YALÇIN به طول عمر بیشتر و کارایی بهتری دست خواهد یافت.

فروش دستگاه پرس کاه شرکت YALÇIN ترکیه: دستگاه بستهبندی کاه چیست و چه کاربردی دارد؟

نکات تکمیلی در عیبیابی و نگهداری دستگاه پرس کاه YALÇIN چیست؟

در این مطلب، به برخی نکات تکمیلی و مهم در زمینه عیبیابی و نگهداری دستگاه پرس کاه YALÇIN پرداخته خواهد شد.

1. آموزش و آگاهی:

- کاربران باید با عملکرد و کاربری دستگاه آشنا باشند. آموزشهای تولید کننده باید بهطور دقیق دنبال شود. آگاهی از نحوه استفاده صحیح و پیشگیری از خطاها از موارد اساسی است.

2. چکلیست نگهداری:

- استفاده از چکلیست نگهداری به منظور انجام دورههای منظم نگهداری و عیبیابی میتواند به جلوگیری از مشکلات بزرگتر کمک کند. این چکلیست باید شامل تمامی نقاط کلیدی دستگاه باشد.

3. مراقبت از سیستم الکتریکی:

- سیستمهای الکتریکی به دقت بالایی نیاز دارند. بررسی دورهای کابلها، اتصالات الکتریکی، و از بین بردن هر گونه خرابی یا تغییرات در سیمها از اهمیت ویژه برخوردار است.

4. نگهداری فیلترها:

- فیلترهای مختلف در دستگاه برای جلوگیری از ورود ذرات غیرمطلوب به سیستم استفاده میشوند. نگهداری و تعویض منظم فیلترها به پایداری سیستم کمک زیادی میکند.

نمایندگی و قیمت فروش دستگاه پرس کاه YALÇIN: سیستمهای کنترل، عیبیابی و نکات نگهداری اجزاء دستگاه

5. ارتباط با تولید کننده:

- هرگونه مشکل یا عدم صحت در عملکرد دستگاه باید به تولید کننده گزارش شود. ارتباط مستقیم با تولید کننده به بهبود سریعتر و اثربخشتر مشکلات کمک میکند.

6. برنامهریزی تعمیرات:

- برنامهریزی تعمیرات دورهای و پیشگیرانه میتواند از ایجاد مشکلات بزرگ در آینده جلوگیری کند. همچنین، تعمیرات ناگهانی را کاهش داده و به بهرهوری دستگاه افزوده میشود.

7. استفاده از لوازم یدکی اصلی:

- هنگام تعویض قطعات یدکی، از لوازم اصلی تولید کننده استفاده شود. استفاده از لوازم کپی و ناسازگار میتواند به عملکرد دستگاه آسیب برساند.

8. انتخاب و نگهداری لوازم یدکی:

- انتخاب لوازم یدکی با کیفیت و تأکید بر استفاده از مواد اصلی از اهمیت بالایی برخوردار است. لوازم یدکی معتبر تولید کننده برای حفظ کارایی بهتر و جلوگیری از مشکلات غیرمنتظره حیاتی است.

قیمت دستگاه پرس کاه YALÇIN: اجزاء و اصول عملکرد دستگاه

9. ایمنی و آموزش کاربران:

- ایمنی در استفاده از دستگاه اولویت بالایی دارد. کاربران باید با تمامی فرآیندهای ایمنی آشنا شده و توجه به دقت در اجرای آنها داشته باشند.

10. اطلاع رسانی در مورد بهروزرسانیها:

- در صورت انجام بهروزرسانیها یا ارتقاء قطعات، اطلاعات کامل به کاربران اطلاعرسانی شود. این اقدام به افزایش عمر مفید و بهرهوری دستگاه کمک میکند.

11. تستهای دورهای:

- انجام تستهای دورهای بر روی دستگاه، به شناسایی زودهنگام مشکلات و افزایش اطمینان از عملکرد صحیح کمک میکند.

12. انبار کردن مناسب:

- در صورت عدم استفاده از دستگاه به مدت طولانی، انبار کردن در محیط خشک و خنک با استفاده از پوششهای مناسب ضروری است.

13. تعمیرات تخصصی:

- تعمیرات بزرگتر و تخصصی باید توسط تیم فنی متخصص انجام شود. در صورت مشاهده هر گونه نقص یا مشکل، به تعمیرگاه معتبر مراجعه شود.

نمایندگی دستگاه پرس کاه: مشخصات فنی، عملکرد و ارزیابی دستگاه پرس کاه YALÇIN

برای خرید و دریافت اطلاعات بیشتر از دستگاه پرس کاه YALÇIN، شما میتوانید با مدیر فروش شرکت جاوید کشت لیزری، آقای مهندس مردانی (شماره تماس: 09121537060) تماس حاصل نمایید و یا از طریق پیام رسانهای ایتا و واتساپ به ایشان پیام ارسال نمایید. این نمایندگی انحصاری، بهترین خدمات و تجربه خرید، به عنوان یک گارانتی اعتباری و کیفیتی به مشتریان خود ارائه می دهد.

نمایندگی فروش دستگاه پرس کاه YALÇIN : سیستم حرکتی، منابع انرژی، سیستم بستهبندی و مزایای دستگاه