stages of corn silage (corn silage)

javid keshtleyzeri Co.ltd

Corn silage, first part - harvesting stage

Corn silage usually has two meanings: the first one means a building or a place where the chopped corn plant is stored and kept, and the second one is the final product of the fermentation of the chopped corn plant in an anaerobic environment. In this text, the term silage is used in the second case. Different management methods used for corn silage can affect the quality and quantity of its nutrients. In addition to the method of cultivation, the selection of the appropriate stage of maturity for harvest and the type of hybrid are among the most important management factors that affect the nutritional value of silage. In other words, the production of corn silage with high dry matter and the production of more milk from the cows that consume it depends on harvesting it at the appropriate stage of maturity and hybrid type.

Various studies have shown that with the increase in the age of the plant, the amount of dry matter of the corn plant increases, which is due to the increase in the amount of seeds in the corn plant. On the other hand, the amount of plant dry matter can be estimated by the stage or degree of seed maturity. Also, the ripening of the seed is estimated by the position of the milky line in it. The milky line is the white line that separates the solid starch part from the milky part of the seed. This line is revealed at the beginning of the dough stage and moves towards the bottom of the grain as the age of maturity increases. For example, if the milk line is in the middle of the seed, the age of the plant is mentioned as milk line ½. On the other hand, when the corn plant reaches full maturity, another line called the black line appears at the end of the seeds.

milky line:

Different researches have shown that as the age of the plant increases from the stage of milking the grain to the stage of two-thirds of the milk line, the amount of starch and energy increases and the percentage of cell wall, cell wall without hemicellulose (ADF) and crude protein of the plant decreases, but from the stage Above until the black line stage, the percentage of these foods remains constant or decreases depending on the type of hybrid, the method of cultivation and other factors.

Examining the effect of corn silages with different moisture levels on dry matter consumption and milk production in dairy cows has shown that silages with more dry matter increased the consumption of dry matter and milk production in cattle, which is related to the increase in the amount of starch and There was a decrease in the percentage of cell wall in the silos that had the percentage of dry matter.

Considering the above, the best time to harvest corn is between half and two-thirds of the milk line, which is more than 30% based on the dry matter of the plant in these stages.

Corn silage, second part - storage process

In the first part of corn silage, information was presented about the importance of corn harvesting time. In this section, the processes that take place in a silo will be explained.

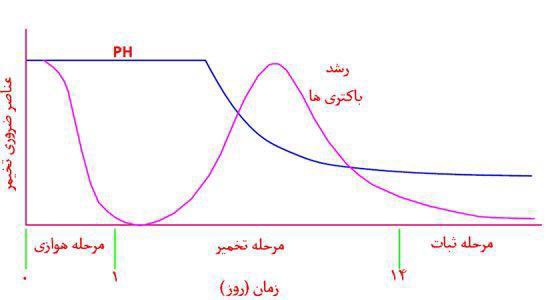

The ensiling process is generally divided into 4 stages, which are:

A- Aerobic Phase

This period begins with harvesting and filling the silo and continues from a few hours to several days depending on the amount of air in it. In this stage, two categories of degradation agents are active, the first is plant enzymes and the second is aerobic microbes such as yeasts and molds, the result of which is the production of gas (mainly heat) and as a result, the loss of silage food. The speed of filling and the amount of silage pounding are factors that determine the amount of available air. In other words, if the silo is filled late or if the silo is not pounded well, more air remains between its particles and causes more activity of these two categories of degradation factors.

B- Fermentation Phase:

This period begins with the exhaustion of oxygen in the silo. In this period, two types of microbes are activated, the first one is the beneficial microbes, which are the lactic acid bacteria that produce lactic acid by consuming water-soluble carbohydrates, which is stronger than other organic acids in the silo. They are responsible for reducing silage pH. On the other hand, the decrease in pH continues to the point where most microbes and biological activities are stopped.

Non-beneficial microbes, such as enterobacteria and clostridia, are another category and work in this stage. High pH and humidity (more than 75%) are suitable conditions for the growth and activity of this group. These microbes, in addition to competing with lactic acid bacteria in the consumption of sugars that can be used in silage, on the other hand, by breaking down proteins, they reduce the nutritional value of silage and produce butyric acid and toxic compounds such as biogenic amines, which have the effect of It will have a negative effect on the palatability of the silage product and the health of the trap.

In some sources, the initial stage of the fermentation stage has been separated and it has been determined as the lag phase. At this stage, the cell membrane of the plant is destroyed by microorganisms and they start to grow in the cell fluid. The duration of this stage is one day.

C-Stable Phase:

This period starts with lowering the pH to the point where most of the microbes are inactive and this phase continues until the air enters the silo.

The processes that happen inside the silo until it is used

D- Remove Phase:

This period begins as soon as the silage is exposed to air. During the harvesting of silage for livestock feeding, this is inevitable, but aerobic spoilage by microbes such as yeasts and molds can start earlier due to damage to the silage cover.