در این بخش انواع مواد و علوفههایی قابلیت سیلاژ شدن را دارند را بررسی می کنیم و در ادامه چگونگی تولید علوفه سیلویی بررسی می شود.

برای دریافت اطلاعات در مورد دستگاه بسته بندی علوفه و دستگاه سیلاژ علوفه، قیمت خرید دستگاه بسته بندی علوفه و مشاوره خرید کافی است با مدیر فروش شرکت جناب آقای مهندس مردانی با شماره همراه 09121537060 تماس بگیرید و یا از طریق پیام رسان ایتا و واتساپ به ایشان پیام ارسال نمایید.

در این بخش علوفه های مناسب برای سیلاژ علوفه شدن بررسی می گردد:

سیلاژ سورگوم چیست؟ سیلاژ ذرت خوشه ای چیست؟

چگونه علوفه سیلویی تولید میشود؟

در ادامه مطالب فوق بررسی می شوند.

برای دریافت اطلاعات در مورد دستگاه بسته بندی علوفه و دستگاه سیلاژ علوفه، قیمت خرید دستگاه بسته بندی علوفه و مشاوره خرید کافی است با مدیر فروش شرکت جناب آقای مهندس مردانی با شماره همراه 09121537060 تماس بگیرید و یا از طریق پیام رسان ایتا و واتساپ به ایشان پیام ارسال نمایید.

کلمات کلیدی: قیمت دستگاه سیلاژ علوفه,قیمت دستگاه بسته بندی علوفه,فروش دستگاه سیلاژ علوفه,فروش دستگاه بسته بندی علوفه,خرید دستگاه سیلاژ علوفه,خرید دستگاه بسته بندی علوفه,دستگاه بسته بندی علوفه,دستگاه سیلاژ علوفه,دستگاه سیلاژ ذرت علوفه ای,دستگاه سیلاژ تفاله مالت,دستگاه سیلاژ ذرت,دستگاه بسته بندی ذرت علوفه ای,قیمت دستگاه سیلاژ ذرت علوفه ای,قیمت دستگاه سیلاژ,فروش دستگاه سیلاژ,دستگاه سیلاژ تفاله چغندرقند,دستگاه بسته بندی تفاله چغندرقند ,دستگاه سیلاژ یونجه,قیمت دستگاه سیلاژ یونجه,فروش دستگاه سیلاژ یونجه,قیمت دستگاه سیلاژ مالت علوفه ای,خرید دستگاه سیلاژ یونجه

ذرت علوفه یکی از بهترین خوراکها برای دام است، ذرت علوفهای بهدلیل وجود کافی مواد قندی و سایر مواد غذایی و شکل ظاهری مناسب آن، تاکنون گیاهی بسیار خوب برای سیلاژ کردن میباشد و به همین دلیل سطح زیر کشت آن در کشورهای مختلف جهان، گسترش زیادی یافته است.

ذرت علوفهای سیلاژ شده، غذای خوشخوراکی برای دامها است. اگر مقداری مکملهای پروتئیندار و نمکهای معدنی به آن اضافه شود، خوراک مناسبی برای نشخوارکنندگان است. برای افزایش مقدار پروتئین سیلوی ذرت میتوان با استفاده از مواد ازته ارزان قیمت مانند اوره و ترکیبات آمونیومدار، آن را غنیسازی کرد.

از ترکیباتی که مواد آهکی دارند مانند کربنات کلسیم و فسفات آمونیوم برای جبران کلسیم و فسفر خوراک تهیه شده میتوان استفاده کرد، تولید انرژی سیلوی ذرت برای شیرآوری حدود ۳۰ درصد نسبت به یونجه خشک، بیشتر است.

سیلوی ذرت ازنظر تولید انرژی برای پروار شدن دام، حدود ۱/۵ برابر یونجه خشک بازدهی دارد. البته پروتئین خام آن نسبت به یونجه خشک، پایینتر است که با افزودن مکملهای پروتئیندار، این کمبود جبران میشود.

سیلاژ سورگوم چیست؟ سیلاژ ذرت خوشه ای چیست؟

- سورگوم یک گیاه علوفهای با ارزش است که شاخ و برگ زیادی که مواد قندی بسیاری دارد، تولید میکند. سورگوم در مناطق گرمسیری شاید بهترین علوفه سیلویی باشد. در مناطقی که آب و هوای معتدل و یا سردی دارد، رقمهایی از این گیاه تولید میشود که علوفه خوب و زیادی تولید میکند.

اگر این علوفه، زمان خمیری شدن دانهها، برداشت شود، دارای حدود ۲۰ تا ۳۰ درصد ماده خشک است.

- میزان عملکرد تولید این علوفه در هکتار میتواند مانند ذرت علوفهای باشد در حالی که نیاز آبی آن، کمتر از ذرت است.

- اگر سورگوم و یا ذرت علوفهای در زمان مناسب برداشت شود، ارزش غذایی علوفه سیلاژ شده آنها، مانند هم خواهد بود.

- از گیاهانی که میتوان آنها را سیلاژ کرد، جو، تریتیکاله ارزن، سودان گراس، گندم، یونجه و انواع شبدر را میتوان نام برد. همچنین تفاله و بقایای انواع میوهها و محصولات سبزی و صیفی را در شرایط مناسب میتوان به خوبی سیلاژ کرد.

چگونه علوفه سیلویی تولید میشود؟

• مرحله اول

پس از سیلاژ کردن علوفه، مقداری هوا بین فضاهای خالی توده علوفه شده، باقی میماند. در اولین مرحله، مواد قندی که در مجاورت این هوای باقی مانده وجود دارد، شروع به سوخت وساز میکند تا اینکه اکسیژن موجود به مصرف رسیده و تمام شود.

هنگام سیلاژ کردن باید دقت کرد که توده علوفه به بهترین روش فشرده شود و تا آنجا که امکان دارد، هوایی بین فضای علوفه، وجود نداشته باشد.

• مرحله دوم

چند ساعت بعد از سیلاژ کردن، تخمیر در محیط بدون هوا، شروع میشود. در این مرحله باکتریهای مفیدی که موجب به عمل آمدن و تخمیر علوفه سیلاژ میشوند (یعنی باکتریهای الاکتیک) تکثیر شده و تعداد آنها به سرعت افزایش مییابد.

زیاد شدن این باکتریهای مفید سبب میشوند موجودات زیانآوری مانند مخمرها، قارچها و باکتریهای تخریبکننده، ازبین بروند. این موجودات مفید با تخمیر مواد قندی سبب تولید اسیدهای مفیدی میشوند که این اسیدها سبب ترش شدن محیط سیلاژ میشوند. اسیدی و یا غیراسیدی بودن محیط سیلاژ را در اصطلاح علمی (پ.هاش) میگویند.

مرحله تخمیر تا زمان پایداری و یا ثابت شدن فعالیتهای شیمیایی سیلو، ادامه پیدا میکند. اگر هوای توده علوفه سیلاژ بهخوبی خارج نشود و یا اگر رطوبت سیلاژ بیش ازحد باشد و یا میزان قند علوفه پایین باشد، ترش شدن به کندی انجام میشود.

اگر چنین شرایطی در سیلاژ بهوجود آید، دستهای از باکتریهای مضر فعال میشوند و با سوخت وساز مواد قندی باقیمانده، مواد دیگری تولید میشود که موجب فساد علوفه سیلاژ شده، میشوند. اگر این حالت ادامه پیدا کند، پروتئین علوفه کمکم ازبین میرود و ارزش غذایی مواد کاهش مییابد و توده سیلاژ شده فاسد میشود.

بنابراین رعایت روش درست سیلاژ کردن در حفظ کیفیت غذایی علوفه، بسیار مهم است. سرعت ترش شدن مواد در سیلو، اهمیت زیادی دارد. باید دقت کرد که مقدار اسیدی شدن مناسب سیلاژ (پ -هاش) بین ۳/۵ تا 4/5 باشد.

اگر هوای توده علوفه سیلاژ شده بهخوبی خارج نشود، مواد قندی گیاه با اکسیژن هوا، ترکیب میشود و در پایان آب، گاز کربنیک و انرژی بهصورت گرما آزاد میشود و کمکم علوفه سیلاژ شده، گرم میشود. در این شرایط، محیط برای رشد و تکثیر قارچ، کپک و موجودات زندهای که در هوا فعالیت میکنند، فراهم شده که درنتیجه آنها شروع به فاسد کردن مواد غذایی توده علوفه شده، میکنند.

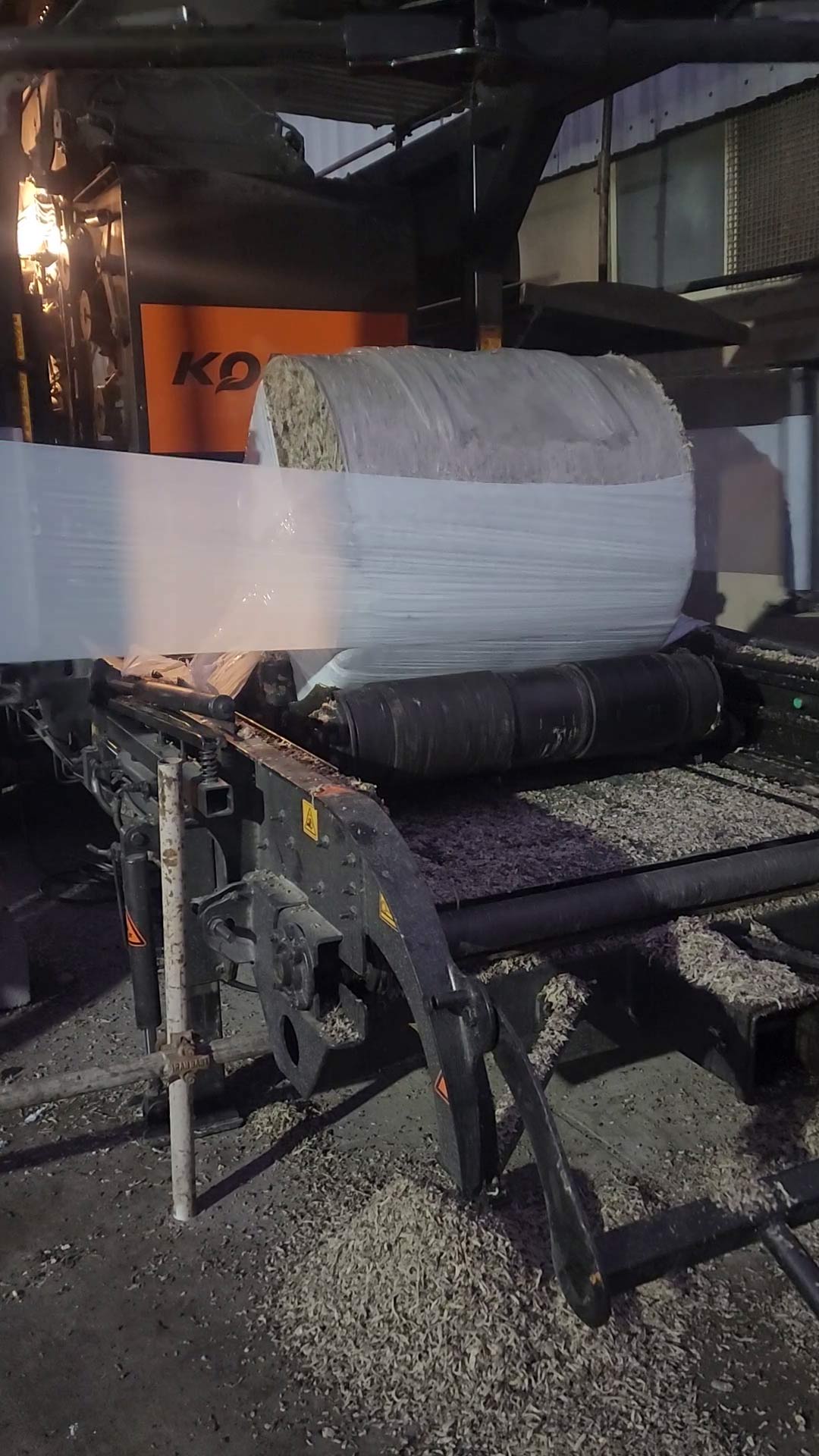

مطمئنا با استفاده از ماشین آلات پیشرفته بسته بندی علوفه و سیلاژ انواع علوفه با کیفیت، می توانید تاثیر بسزایی در فرآوری محصولات دامی دارد، با کلیک بر روی تصویر و لینک زیر می توانید با انواع دستگاه های سیلاژ علوفه آشنا شوید:

بارگیری، نصب و راه اندازی دستگاه بسته بندی علوفه - فروش ویژه دستگاه سیلاژ علوفه

برای دریافت اطلاعات در مورد دستگاه بسته بندی علوفه و دستگاه سیلاژ علوفه، قیمت خرید دستگاه بسته بندی علوفه و مشاوره خرید کافی است با مدیر فروش شرکت جناب آقای مهندس مردانی با شماره همراه 09121537060 تماس بگیرید و یا از طریق پیام رسان ایتا و واتساپ به ایشان پیام ارسال نمایید.

کلمات کلیدی: قیمت دستگاه سیلاژ علوفه,قیمت دستگاه بسته بندی علوفه,فروش دستگاه سیلاژ علوفه,فروش دستگاه بسته بندی علوفه,خرید دستگاه سیلاژ علوفه,خرید دستگاه بسته بندی علوفه,دستگاه بسته بندی علوفه,دستگاه سیلاژ علوفه,دستگاه سیلاژ ذرت علوفه ای,دستگاه سیلاژ تفاله مالت,دستگاه سیلاژ ذرت,دستگاه بسته بندی ذرت علوفه ای,قیمت دستگاه سیلاژ ذرت علوفه ای,قیمت دستگاه سیلاژ,فروش دستگاه سیلاژ,دستگاه سیلاژ تفاله چغندرقند,دستگاه بسته بندی تفاله چغندرقند ,دستگاه سیلاژ یونجه,قیمت دستگاه سیلاژ یونجه,فروش دستگاه سیلاژ یونجه,قیمت دستگاه سیلاژ مالت علوفه ای,خرید دستگاه سیلاژ یونجه